If you’re an industry professional working with Perspex, a specialized form of Acrylic sheets, mastering advanced cutting techniques is non-negotiable. This guide aims to delve into those techniques that can elevate your craftsmanship from amateur to a Perspex cutting expert.

Perspex is an acrylic material that marries durability with flexibility, making it ideal for a variety of industrial applications. Unlike regular glass, it’s shatter-resistant and lighter, which explains its widespread use. When cutting Perspex, understanding its molecular structure can greatly improve your results.

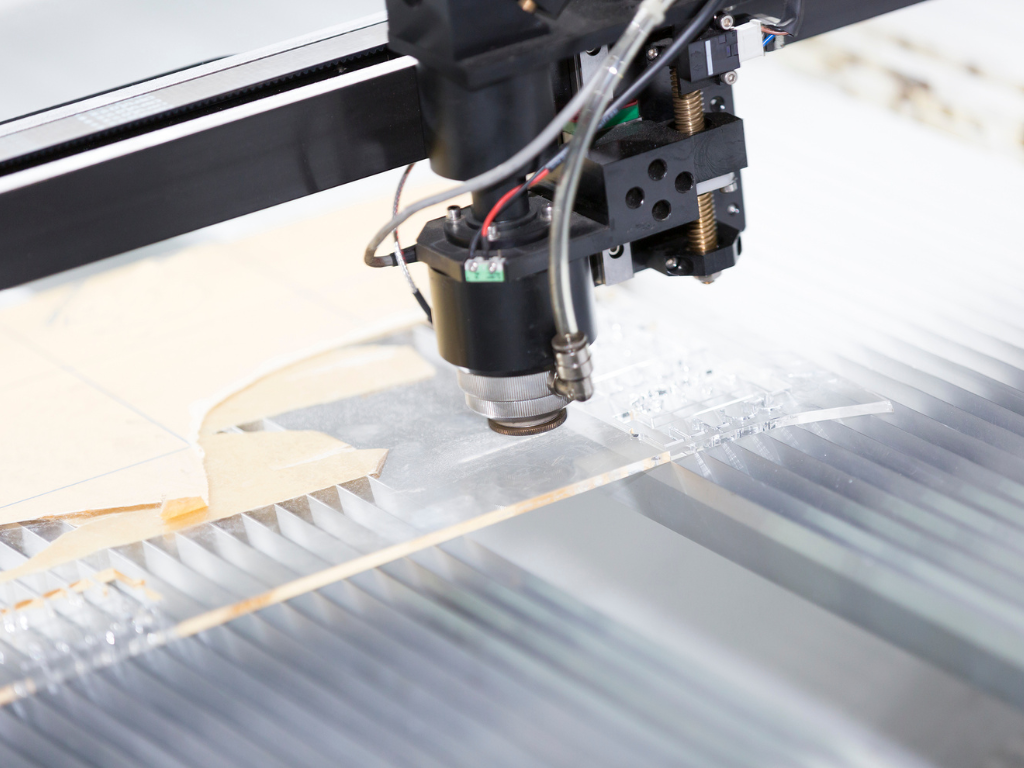

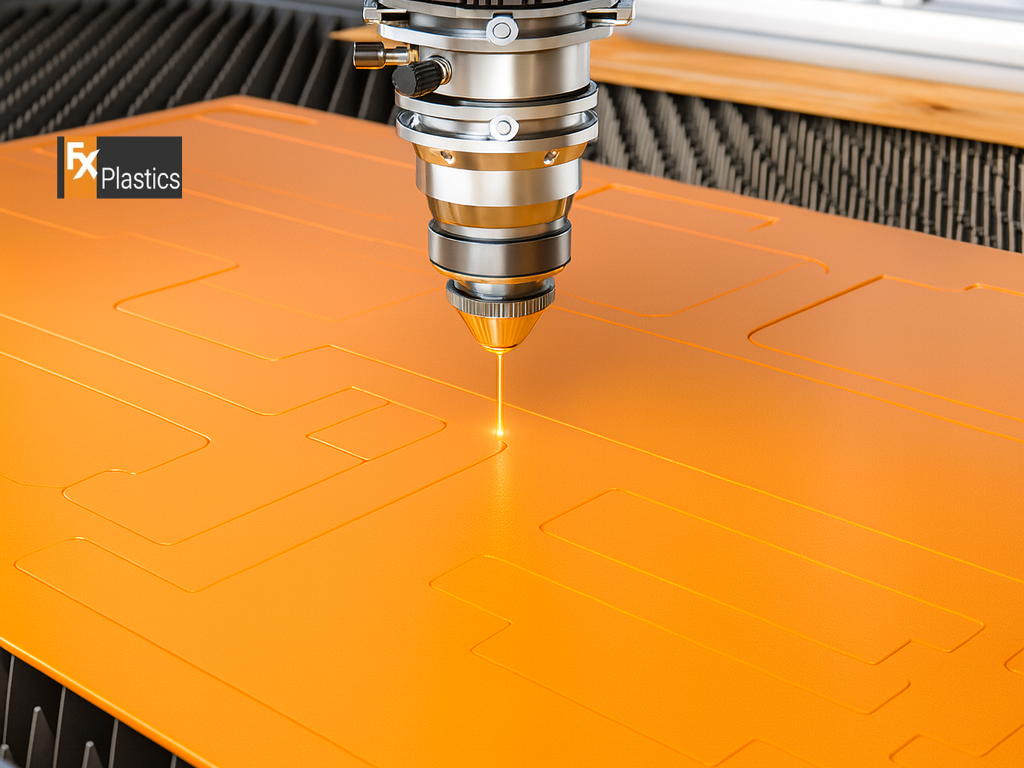

Laser cutting and traditional methods have their places, but how do you choose the right one for your project?

Your choice of tool can dramatically affect the quality of your Perspex cut.

Optimal cutting often begins at the design stage. Advanced software can streamline your workflow, reduce errors, and improve efficiency.

Temperature plays a surprisingly significant role in how well Perspex can be cut.

As projects become more complex, a single-axis machine often won’t suffice.

Mastering the balance between feed rate and spindle speed can make or break your Perspex cutting project.

Actionable Tip: Experiment with different combinations of feed rate and spindle speed on scrap material before committing to the final piece.

While Perspex is more forgiving than glass, it still requires stringent safety measures.

To ensure that your tools are always up to the task, regular maintenance is a must.

Nothing is more frustrating than inconsistent cuts. Implementing a robust quality control process can save both time and resources.

Advanced Perspex cutting is both an art and a science. By understanding the nuances of the material and the capabilities of your tools, you can elevate your craft to new heights. Whether you’re working on a custom piece or mass-producing items, the techniques covered in this guide offer a roadmap to excellence in Perspex cutting.

More Blog

Modern businesses want materials that look good, last long, and offer creative flexibility. That’s why

When precision and design accuracy matter, cnc cutting services are a perfect solution. These services

In recent years, more people have started to ask questions about the environmental impact of

When people hear Design and Fabrication, they often think of big metal structures. But in