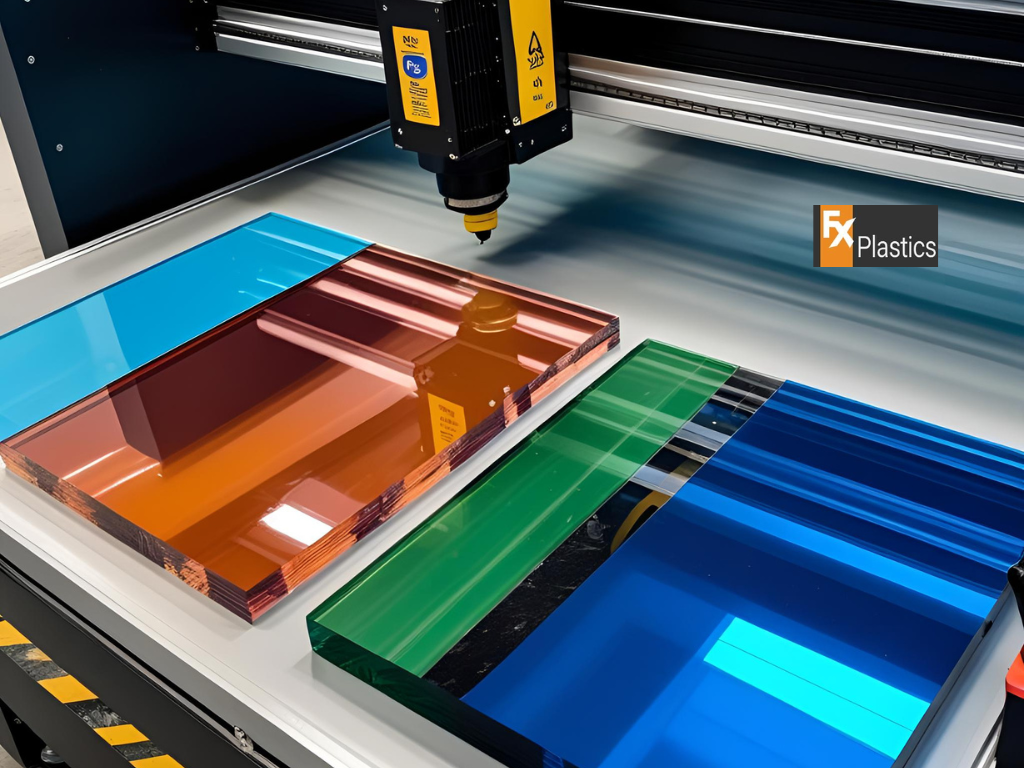

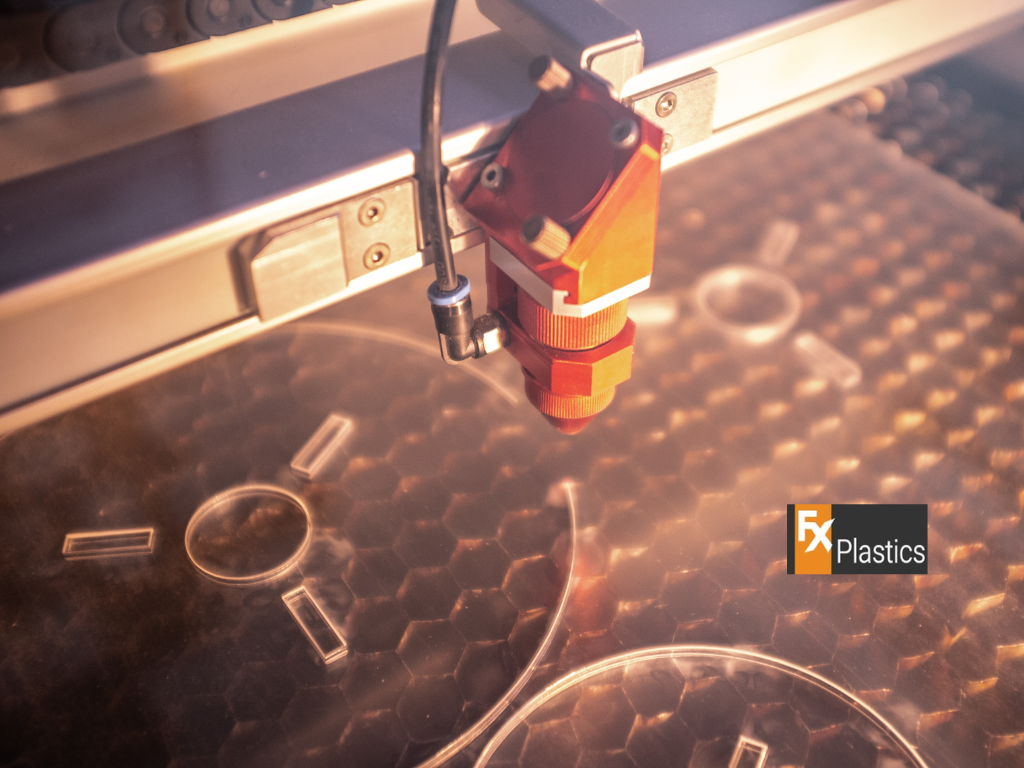

Acrylic laser cutting sydney is a precise method used to cut and engrave acrylic sheets using a high-powered laser. This technique is widely used in Sydney for creating intricate designs and customized products due to its accuracy and efficiency. The laser beam melts the acrylic along the cutting path, resulting in clean, smooth edges without the need for additional finishing. This process is ideal for producing detailed and complex shapes that are difficult to achieve with traditional cutting methods.

Acrylic is a popular material for custom products because of its versatility, durability, and clarity. It is lightweight yet strong, making it an excellent choice for various applications, including Covid-19 protective shields. Acrylic is also highly transparent, providing clear visibility while acting as a barrier. Additionally, it is easy to clean and maintain, ensuring hygiene standards are met in environments where cleanliness is critical. These properties make acrylic an ideal material for custom products created through laser cutting.

Acrylic laser cutting sydney offers unparalleled precision and accuracy, which is crucial for producing effective Covid-19 protective shields. The laser cutting process allows for the creation of custom shapes and sizes tailored to specific needs, ensuring a perfect fit and optimal protection. The precision of laser cutting ensures that all edges are smooth and safe, reducing the risk of injury and improving the overall quality of the protective shields.

Acrylic shields produced through laser cutting are both durable and clear, providing long-lasting protection without compromising visibility. The strength of acrylic ensures that the shields can withstand daily use and resist impacts, making them ideal for high-traffic areas and frequent handling. The clarity of acrylic allows for unobstructed communication and interaction, which is essential in settings like offices, retail stores, and healthcare facilities. This combination of durability and clarity makes acrylic an excellent choice for protective shields.

Face shields and barriers are essential for personal protection and preventing the spread of Covid-19. Laser-cut acrylic face shields offer full-face coverage, protecting the wearer from respiratory droplets. These shields are lightweight, comfortable, and can be worn for extended periods without causing discomfort. Acrylic barriers, such as those used on countertops and desks, provide a physical separation between individuals, reducing the risk of virus transmission in shared spaces. These barriers can be custom-sized to fit specific areas, ensuring comprehensive coverage.

Desk dividers and sneeze guards are vital in maintaining social distancing and creating safe environments in workplaces and public spaces. Laser-cut acrylic desk dividers can be easily installed on workstations to provide individual protection while allowing for collaboration and communication. Sneeze guards, often used in food service areas and checkout counters, act as a shield against respiratory droplets, safeguarding both employees and customers. Customizing these products with acrylic laser cutting ensures they meet specific spatial and functional requirements.

The first step in customizing acrylic shields using laser cutting is designing the shapes and sizes that meet the specific needs of the application. This involves creating digital designs that outline the dimensions and contours of the protective shields. Advanced design software allows for precise control over the design process, enabling the creation of intricate patterns and detailed shapes. Custom designs can include features such as cutouts for ventilation, slots for mounting, and ergonomic curves for enhanced comfort.

When designing Covid-19 protective shields, it’s crucial to focus on maximizing their protective capabilities. The design should ensure that the shield covers all necessary areas to block respiratory droplets effectively. For face shields, this means providing full-face coverage, including the sides and below the chin, to protect against splashes and sprays from all angles. For desk dividers and barriers, the height and width should be sufficient to create an effective barrier between individuals. Additionally, incorporating curves and rounded edges can improve the structural integrity of the shields and reduce the risk of injuries from sharp edges.

User comfort and practicality are key factors in the design of protective shields. For face shields, lightweight materials and adjustable headbands enhance comfort, allowing users to wear them for extended periods without discomfort. Anti-fog coatings and ventilation slots can prevent fogging and improve breathability. For desk dividers and sneeze guards, easy installation and removal are essential for flexibility and convenience. Providing options for customization, such as adding pass-through windows for transactions or incorporating branding elements, can enhance the practicality and aesthetic appeal of the shields.

In office environments, customized acrylic shields play a vital role in maintaining a safe and productive workspace. Desk dividers and partition screens help create individual workstations, reducing the risk of virus transmission between employees. Conference rooms and common areas can also be equipped with barriers to allow for safe meetings and interactions. The transparency of acrylic ensures clear visibility and communication, maintaining a collaborative atmosphere while providing necessary protection.

In retail and customer service settings, acrylic shields are essential for protecting both employees and customers. Countertop barriers and sneeze guards at checkout stations provide a physical barrier that helps prevent the spread of respiratory droplets. Customized shields can be designed to fit specific counter configurations and include features such as transaction windows or slots for documents and payments. This not only enhances safety but also ensures smooth and efficient service. By installing protective shields, businesses can create a safer shopping experience and instill confidence in their customers.

Choosing the right acrylic laser cutting service in Sydney involves evaluating the provider’s experience and capabilities. Look for a company with a proven track record in producing high-quality acrylic products and a portfolio showcasing their work. Experience in handling projects similar to yours is a good indicator of their ability to meet your specific needs. Additionally, inquire about their technical expertise and the range of services they offer, from design assistance to finishing touches. A reputable provider should be able to demonstrate their proficiency and reliability through customer testimonials and case studies.

The quality of materials and equipment used by the laser cutting service is crucial for achieving excellent results. Ensure that the provider uses high-grade acrylic that is durable, clear, and suitable for your intended application. The laser cutting equipment should be state-of-the-art, capable of producing precise cuts with smooth edges. Ask about their quality control processes to ensure that each piece meets the required standards. A reliable service provider will be transparent about their materials and methods, giving you confidence in the quality of the final product.

Regular cleaning and disinfecting are essential to maintain the clarity and hygiene of acrylic protective shields. Use a soft cloth and mild soap or a specialized acrylic cleaner to remove dirt and fingerprints without scratching the surface. Avoid using abrasive cleaners or rough materials that can damage the acrylic. For disinfecting, use alcohol-based solutions or disinfectant wipes that are safe for acrylic. It’s important to follow the manufacturer’s guidelines for cleaning and disinfecting to ensure the longevity and effectiveness of the shields.

Preventing scratches and damage is key to maintaining the aesthetic and functional quality of acrylic shields. Handle the shields with care, using protective gloves to avoid fingerprints and smudges. When cleaning, use gentle, circular motions with a soft cloth to minimize the risk of scratches. Store the shields in a safe, dry place when not in use, and avoid stacking them directly on top of each other. If scratches do occur, consider using a specialized acrylic polish to restore the surface. Regular maintenance and careful handling will help keep your acrylic protective shields in top condition, ensuring they provide effective protection for a long time.

More Blog

Laser cut acrylic has become one of the most popular materials for custom projects. Its

Acrylic sheets are a go-to choice for many companies across Western Sydney. They are strong,

When it comes to choosing a perspex sheet sydney customers often ask the same question—should

More people and businesses are making eco-friendly choices these days, and the world of Design