CNC laser cutting and CNC routing and machining serve different purposes when it comes to precision and material handling. CNC laser cutting uses a high-powered laser to cut materials with extreme precision, making it ideal for intricate designs and thin materials. In contrast, CNC routing and machining involve using a rotating cutting tool, allowing for deeper cuts and thicker materials like wood and metal. The key difference lies in the material thickness each method can handle, and their respective roles in the overall design and fabrication process.

While CNC laser cutting is known for its precision, certain intricate designs can pose challenges, especially when working with heat-sensitive materials like Plastic Display. The heat generated during the cutting process may cause warping or cracking in delicate materials. Additionally, highly detailed geometric shapes may struggle to maintain their form, especially in thicker materials. Understanding the limitations of CNC laser cutting ensures that designs are adapted to match its capabilities, with CNC routing and machining often providing a better alternative for specific tasks.

One limitation of CNC laser cutting is its performance with thick materials. Lasers are ideal for cutting thin sheets of materials such as plastics, metals, and wood. However, as the material gets thicker, the laser may struggle to penetrate cleanly, resulting in jagged or uneven cuts. This affects both the design outcome and the efficiency of the project. When working with thicker materials, designers may need to adapt their approach, either by opting for thinner material or adjusting the design to suit the capabilities of the laser.

When dealing with thicker materials like timber wood panel or metal, CNC routing and machining prove to be more efficient than laser cutting. The rotating cutting tools in CNC routing can handle greater depths, making them more suitable for projects that require deep cuts or designs on thick materials. This method is particularly useful in construction and large-scale Design and Fabrication projects where structural integrity and precision are key.

For highly intricate designs, CNC laser cutting can face challenges, particularly with extremely fine details. The laser’s beam, though precise, has a limited width, which makes cutting ultra-fine lines in complex Plastic Display projects difficult. Additionally, the heat from the laser can cause certain materials to melt or warp, compromising the final appearance. When working with delicate designs, it’s essential to consider whether CNC routing and machining would provide a cleaner and more accurate result.

One effective solution for overcoming precision limitations is to combine both CNC laser cutting and CNC routing. For example, laser cutting can be used for high-detail, thin sections of a design, while CNC routing can handle thicker or more complex areas where deeper cuts are required. This hybrid approach ensures precision without sacrificing the integrity or design intent of the project, particularly in Plastic Display applications.

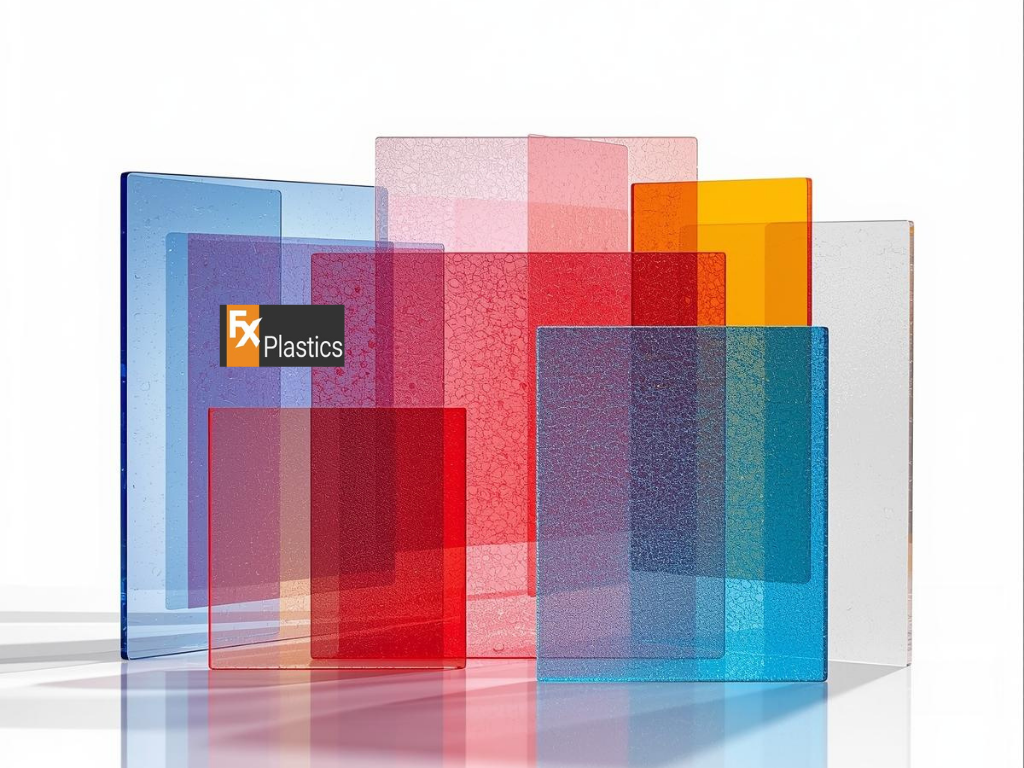

Plastic Displays are commonly used in retail and exhibition environments, but laser cutting these materials can be tricky. The heat generated by the laser often causes warping, cracking, or even discoloration of the plastic. These issues can affect the final look and durability of the display. Understanding the limitations of CNC laser cutting in this context helps in designing projects that avoid these issues.

To overcome the material constraints of Plastic Displays, design modifications can make a significant difference. For instance, opting for thicker plastic sheets or choosing specific types of plastics that handle heat better can improve durability. Additionally, incorporating CNC routing and machining for certain sections of the project can ensure that the final display meets both design and durability expectations.

CNC laser cutting is ideal for straightforward, clean lines, but when it comes to highly complex or geometric designs, especially in intricate patterns, there are limitations. The laser’s beam width, heat output, and the material’s response to the heat all play a part in whether the design will be successful. Thicker materials and complicated geometries may not be fully achievable with laser cutting alone.

To tackle these limitations, designers can adjust their plans by simplifying certain design elements or layering parts of the design for better results. In some cases, using CNC routing and machining alongside CNC laser cutting can help achieve the desired level of intricacy, particularly in burl veneer and detailed Plastic Display work.

The power settings of a CNC laser cutting machine are critical in determining the quality of the cut, especially when working with sensitive materials like plastic display. Too much power can cause the material to warp or burn, while too little power may not penetrate the material fully, leading to incomplete cuts. It’s essential to balance power settings carefully depending on the material’s thickness and the design requirements, ensuring optimal results without damaging the material.

Achieving the perfect balance between power and precision is key to high-quality CNC laser cutting. For complex design and fabrication projects, adjusting the laser’s intensity and speed ensures clean, precise cuts. This becomes especially important when working with materials like plastic display, where even a slight imbalance in power can ruin the entire design. Using lower power for intricate details and higher power for thicker materials can maximise both precision and efficiency.

Both CNC laser cutting and CNC routing and machining offer unique benefits when it comes to detailed fabrication. CNC laser cutting excels in producing sharp, precise cuts, especially for thin materials and intricate designs, but it may struggle with thicker materials or highly detailed patterns that require depth. CNC routing and machining, on the other hand, is ideal for deeper cuts and works better on thicker or tougher materials like wood or metal. Depending on the project’s needs, one method may outshine the other.

For projects that require a mix of fine detail and material versatility, combining CNC laser cutting with CNC routing and machining can be the best approach. Laser cutting can handle the intricate design work, while CNC routing can tackle deeper cuts and more robust materials, ssch as timber wood panel or veneer board. This hybrid approach ensures both precision and durability in the final product, perfect for high-end design and fabrication projects.

As technology advances, innovations in CNC laser cutting are helping overcome some of the traditional limitations of the process. From higher precision lasers to improved material handling capabilities, new advancements are allowing for more complex cuts, better efficiency, and reduced material damage. These innovations are particularly promising for applications like plastic display and burl veneer, where intricatee designs meet challenging material properties.

The future of CNC laser cutting in design and fabrication looks bright, with ongoing developments that promise to push the boundaries of what’s possible. As more industries adopt the technology, we can expect greater integration with CNC routing and machining, creating more versatile solutions for projects that require both detail and robustness. From architectural design to custom plastic display fabrication, the potential for laser cutting continues to expand, offering new possibilities for industries and creators alike.

More Blog

acrylic screens are made from a clear plastic material that offers excellent transparency and strength.

Acrylic fabrication is the process of turning acrylic plastic into finished products that people can

An acrylic screen is designed to handle everyday impact and pressure in a way that

An acrylic screen is a clear and lightweight alternative to glass that is designed for