In recent years, more people have started to ask questions about the environmental impact of materials used in everyday products. Acrylic fabrication is one of those areas under the spotlight. Acrylic is loved for its strength, clarity, and flexibility, but many wonder how sustainable it really is.

The truth is that acrylic, like many plastics, is not biodegradable. This means it doesn’t break down naturally. However, with the right processes, it can be reused, recycled, and made to last much longer than single-use plastics. By looking at how fabrication is carried out and adopting greener methods, businesses can reduce waste while still benefiting from the many advantages of acrylic.

For industries such as retail, design, and construction, sustainability is no longer just a trend. It’s something customers actively look for. Making better choices in Acrylic fabrication not only helps the planet but also shows that companies are serious about long-term responsibility.

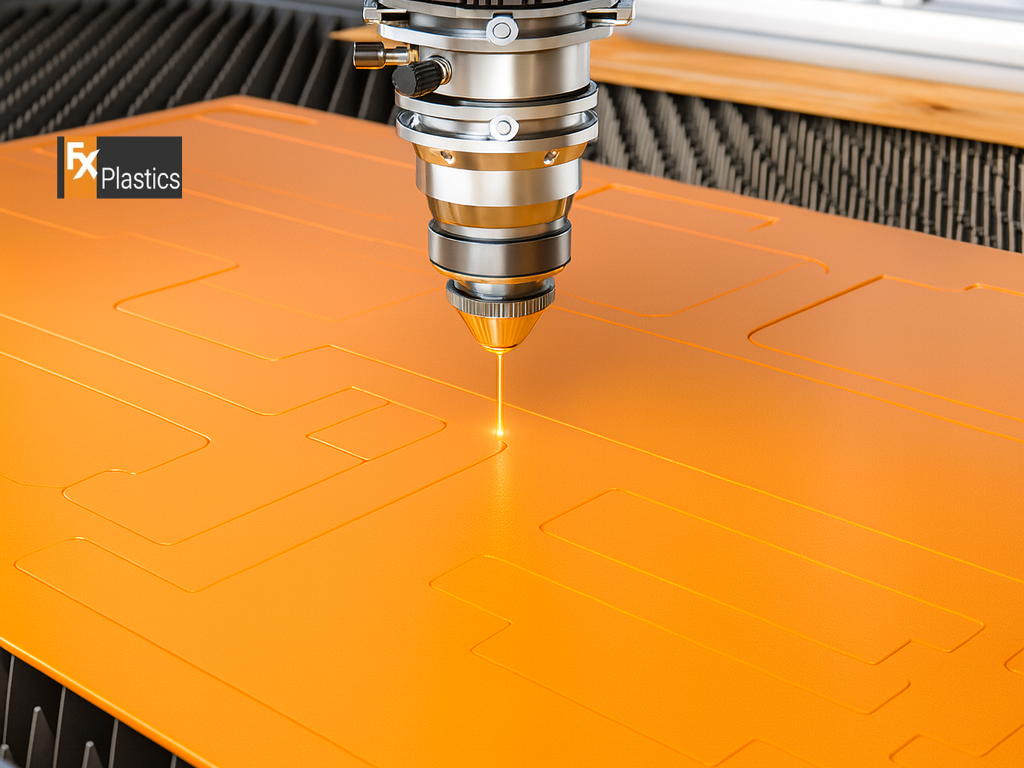

One of the big advantages of Laser Cutting Western Sydney is its ability to make very precise cuts. Unlike traditional cutting tools, lasers can follow detailed patterns without leaving rough edges or excess waste. This means every sheet of acrylic can be used more efficiently, with minimal scrap left behind.

Using the right cutting method also helps reduce the need for rework. In older systems, mistakes often meant wasting a large section of material. With laser accuracy, the process becomes cleaner, faster, and smarter. For businesses, this means fewer offcuts going into landfill and lower costs from wasted material.

By adopting Laser Cutting Western Sydney, many workshops are moving towards greener and more efficient ways of working. It’s a practical step that balances both environmental and financial benefits.

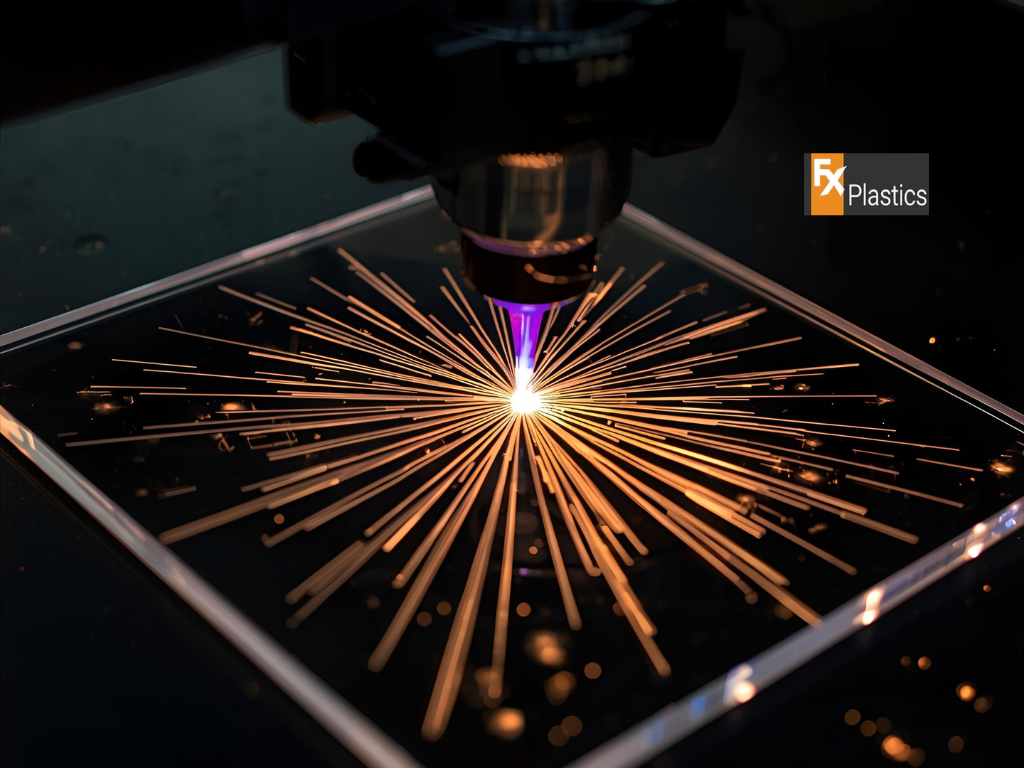

When it comes to efficiency, CNC laser cutting plays an important role in sustainability. CNC stands for computer numerical control, which means the cutting is controlled by a computer program. This process helps achieve consistent results with very little error. Less error means fewer wasted sheets of acrylic. By reducing mistakes, CNC laser cutting ensures that every piece is cut exactly as planned. This accuracy not only saves materials but also reduces energy use since the machine doesn’t need to repeat the same job multiple times.

Another eco-friendly advantage is how CNC technology allows designers to map out cutting patterns in advance. By nesting shapes closely together on a sheet, workshops can maximise the use of each piece of acrylic. This careful planning leads to less waste and a smaller environmental footprint. For businesses wanting to show their commitment to sustainability, using CNC laser cutting is one clear way to make a difference while still delivering high-quality results.

Workshops that focus on laser cutting sydney are now moving towards machines that use less energy while still delivering high performance. Newer models are designed to be faster and more precise, which means less power is wasted during operation. For businesses, this is not only eco-friendly but also cost-effective in the long run.

Another positive shift in laser cutting sydney is the effort to recycle leftover acrylic. Offcuts can often be repurposed into smaller products like signage, display stands, or even craft projects. By reusing materials, workshops reduce the amount of waste that ends up in landfill and create more value from each sheet.

One of the smartest ways to reduce waste is by only buying the amount of material you actually need. This is where perspex cut to size sydney comes in handy. Instead of purchasing full sheets and cutting them down yourself, you can order exactly the right size for your project.

This approach has a few key benefits:

You save money by not paying for material you won’t use.

There’s less chance of offcuts being thrown away.

Projects can be completed faster with ready-to-use panels.

By choosing perspex cut to size sydney, both businesses and individuals can reduce waste and take a simple step towards more sustainable practices.

Since the pandemic, acrylic screens have become common in workplaces, shops, and restaurants. But instead of throwing them away when they’re no longer needed, many businesses are finding creative ways to reuse them. For example, screens can be reshaped into partitions, display panels, or even signage.

Recycling acrylic has always been tricky, but new methods are being developed to make it easier. While not all councils accept acrylic for household recycling, specialised facilities can turn old acrylic screens into reusable material. With progress in this area, the lifespan of acrylic products can be extended well beyond their first use.

Looking ahead, the future of Acrylic fabrication is moving towards greener solutions. Advances in recycling, better energy efficiency in machines, and smarter design practices are all playing a role. Some companies are even exploring biodegradable alternatives that mimic the look and feel of acrylic while being easier to break down.

For now, the best way forward is to focus on long-lasting designs, efficient use of materials, and reusing what we already have. By making these small but important changes, industries and individuals can make Acrylic fabrication more sustainable and environmentally responsible.

More Blog

If you’re running a workshop, signage business, or custom build project in Western Sydney, precision

Supermarkets are busy places where customer interaction happens every few seconds. From checkout counters to

Modern businesses want materials that look good, last long, and offer creative flexibility. That’s why

When precision and design accuracy matter, cnc cutting services are a perfect solution. These services