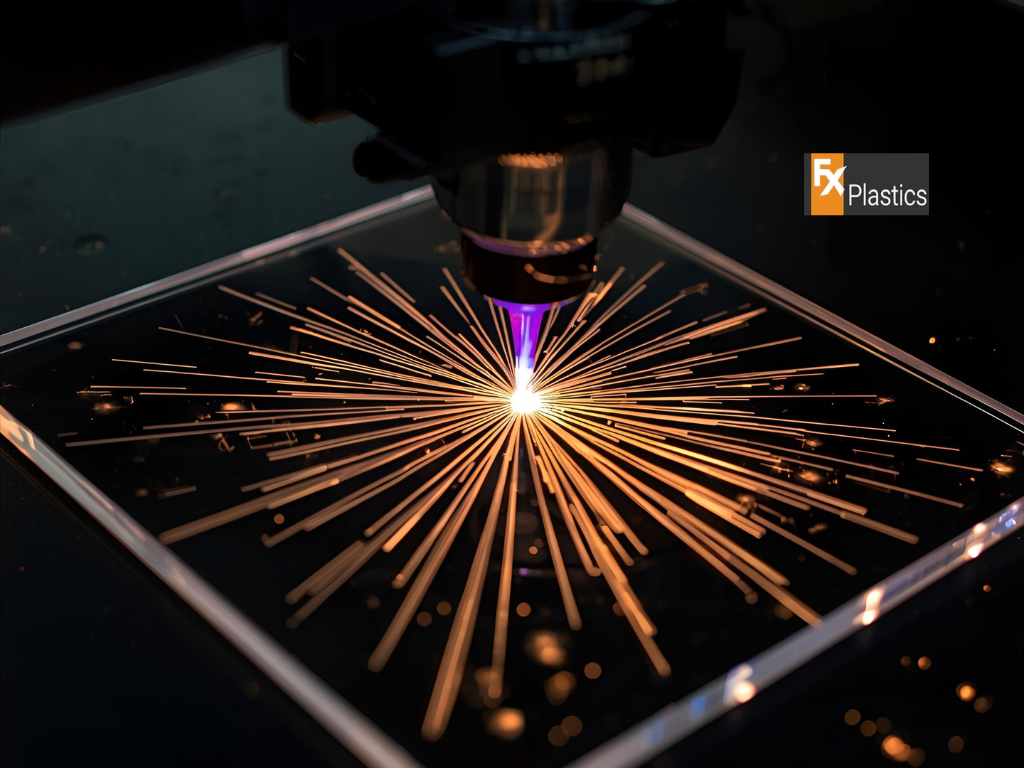

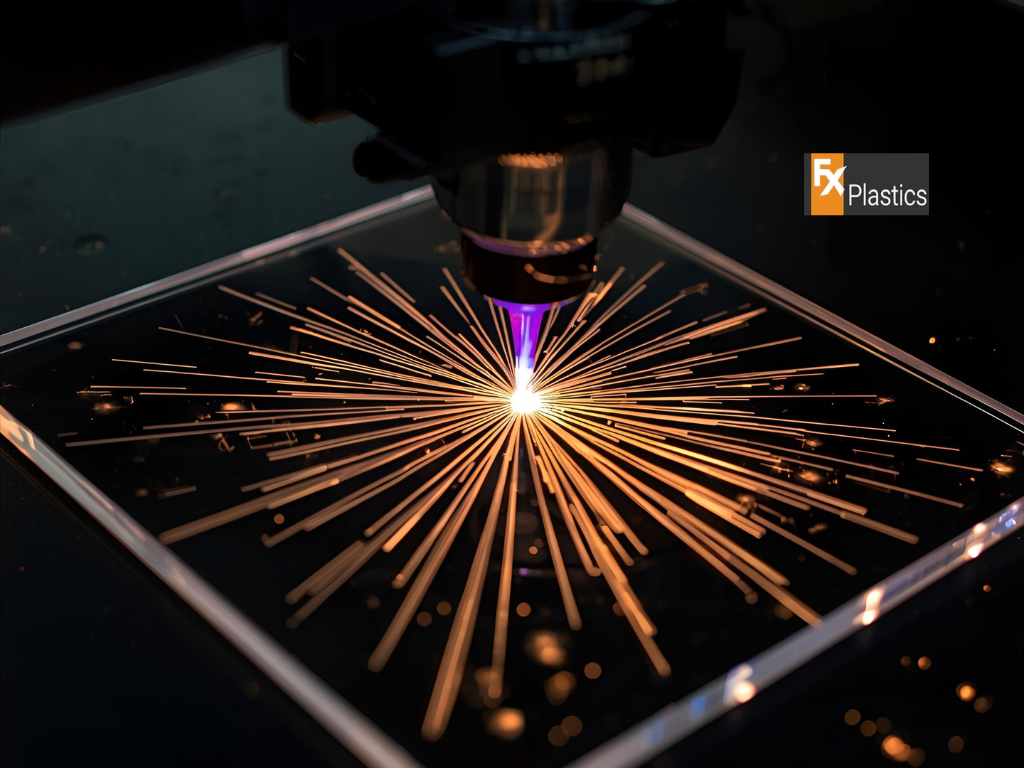

If you’re running a workshop, signage business, or custom build project in Western Sydney, precision and speed are everything. That’s why more fabricators are turning to Laser Cutting Western Sydney services to get the job done right the first time. Laser cutting allows for extremely clean, accurate cuts — no need for manual finishing or edge sanding. And when you’re working with bulk materials or time-sensitive projects, every second saved counts.

Whether you’re making small brackets, signage, furniture panels or cut-to-size components, laser technology gives you:

Local providers in Western Sydney also save you money on shipping and give you direct access to skilled technicians who understand your industry needs.

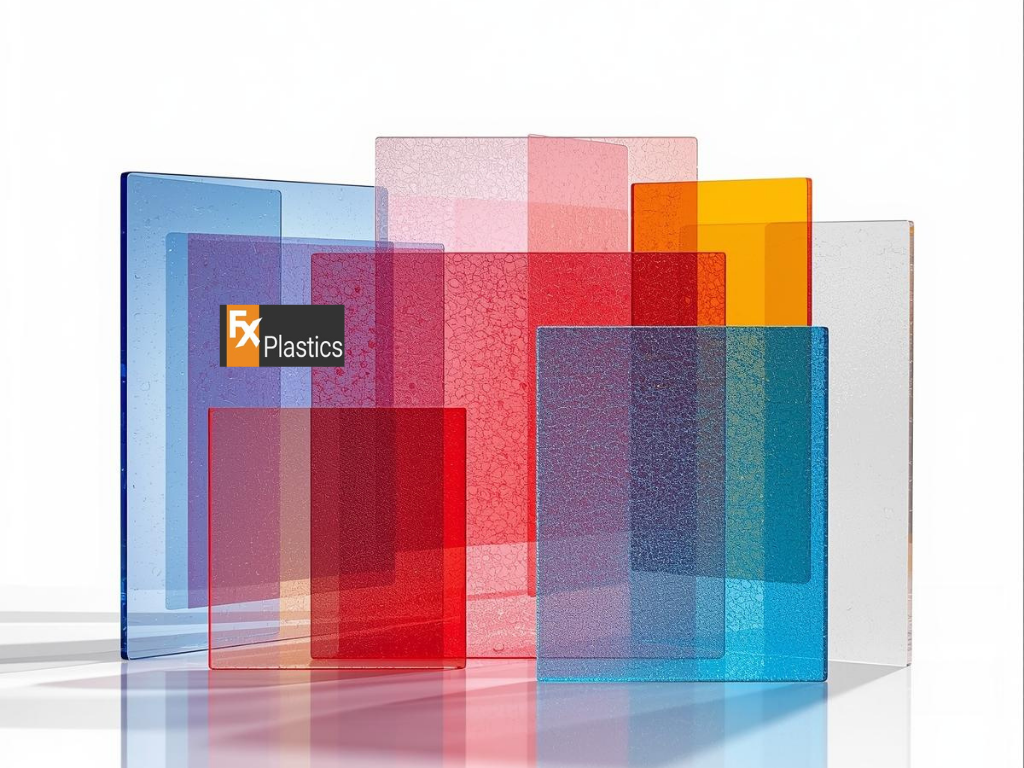

When it comes to Acrylic sheets, laser cutting is hands-down the best method. Whether you’re creating displays, panels, or dividers, laser cutting sydney ensures your acrylic cuts are crystal-clear, smooth, and ready to install without polishing.

Laser technology seals the edges during the cut. This means no cracks, no roughness, and no extra finishing. If you’re working in retail, hospitality, or events, having neat edges on Acrylic sheets makes a huge difference in quality and presentation.

Because laser-cut parts are so accurate, your pieces fit together without fuss. That’s especially useful for custom enclosures, point-of-sale displays, or structural panels. You can rely on your parts being consistent every time, which helps reduce rework and speeds up assembly on site.

If you’re cutting multiple acrylic panels or repeating shapes across a project, using laser cutting sydney with pre-sized Acrylic sheets makes the whole process smoother and more cost-effective.

Acrylic has become one of the most popular materials for custom panels, especially since it’s lightweight, affordable, and easy to clean. With laser cutting acrylic, businesses can quickly produce high-quality screens and partitions for retail counters, waiting rooms, offices, and more. What makes laser cutting acrylic stand out is the detail. You can create curves, cut-outs, ventilation slots, or custom logos with precision — something traditional tools just can’t offer.

It’s also perfect for:

Whether you’re after function or flair, laser-cut acrylic gives you the flexibility to do both.

Over the past few years, clear barrier screens have become essential in many workplaces. From retail counters to medical centres, perspex screens sydney are in high demand for safety and hygiene. Laser cutting allows these screens to be tailored to fit any space. Need a slot for payments or document exchange? Want the edges rounded for safety? Laser machines can do it all with precision.

Whether you’re after freestanding panels or bolted-in screens, the finish is clean and professional. What makes perspex screens sydney even more useful is their clarity and ease of cleaning — two features that matter most in client-facing environments.

Perspex is much lighter than glass and safer to handle. Plus, when you combine it with Laser Cutting Western Sydney services, you get custom sizes ready to go — no trimming required.

This makes installation quick, especially when screens need to be added to desks, shop counters, or reception areas. And when your screens are laser-cut, you know every panel will fit just as expected, with no rough edges or sharp corners.

For signage, partitions, or decorative displays, using an acrylic screen or acrylic screens has become a go-to solution. The material is strong, lightweight, and gives off a polished, modern feel.

Laser cutting takes it to the next level. It enables:

Whether you’re designing something bold for a shopfront or subtle for a museum display, laser-cut acrylic ensures the finished product looks clean and professional. And the consistent quality across multiple acrylic screens means you can easily repeat the design for multiple locations or clients. Another benefit? Laser cutting avoids cracking, chipping or melting — so your acrylic screen will hold up well, even in outdoor or high-traffic areas.

Laser cutting isn’t just for acrylic and Perspex — it’s heavily used in metal work too. For many industrial and fabrication jobs in Western Sydney, laser cutting is the first step before moving on to CNC punching or bending.

Once a metal sheet is cut precisely with Laser Cutting Western Sydney services, it can go straight to a press brake or punching machine for shaping or adding holes. This seamless transition between processes saves loads of time in production.

If you’re making a high volume of brackets, frames, or other structural parts, accuracy matters. Laser cutting gives you consistent results across every piece, meaning fewer mistakes and less material waste. That’s why fabricators often offer laser, bending, and punching under one roof — to help you get a finished product faster, with fewer suppliers involved.

Combining Laser Cutting Western Sydney services with acrylic or metal fabrication is a smart move for businesses looking for precision, speed, and flexibility. Whether you’re cutting Acrylic sheets, designing with acrylic screens, or creating safety panels like perspex screens sydney, laser technology makes the process simple and professional. And when paired with punching or bending, your workflow becomes even more efficient.

More Blog

An acrylic screen is designed to handle everyday impact and pressure in a way that

An acrylic screen is a clear and lightweight alternative to glass that is designed for

Whether you’re styling a café, updating an office, or adding privacy to your home, acrylic

If you’re running a workshop, signage business, or custom build project in Western Sydney, precision