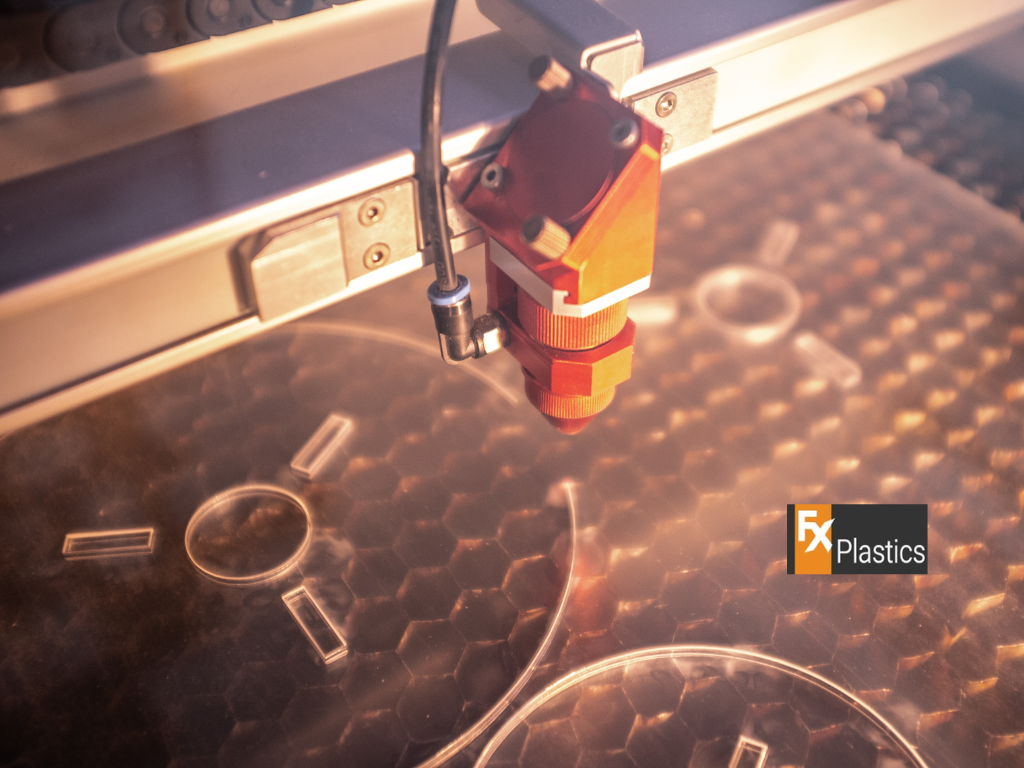

Acrylic laser cutting is a precise and efficient method of cutting acrylic sheets using high-powered lasers. In the context of Acrylic Laser Cutting Sydney, this technique is widely used for creating intricate designs, signage, and custom products. The process involves directing a focused laser beam onto the acrylic material, which heats and vaporises the material along a predefined path, creating clean, sharp edges. It is ideal for producing fine details, complex patterns, and smooth cuts without the need for additional finishing.

There are several methods used to cut materials like acrylic, including Laser Cutting and CNC Cutting. Laser Cutting utilises laser beams for precision and speed, making it ideal for projects requiring fine detail. On the other hand, CNC Cutting involves computer-controlled routers or mills that physically remove material using rotating cutting tools. Both techniques have their own applications, advantages, and limitations, which we will explore further in this content.

One of the key advantages of Laser Cutting technology is its unparalleled precision, especially when cutting acrylic. The focused laser beam can be controlled to within fractions of a millimetre, making it ideal for projects that require intricate details and accuracy. Whether for industrial applications or custom art projects, Acrylic Laser Cutting Sydney allows for highly accurate cuts, reducing the risk of errors or material wastage. This level of precision is particularly beneficial for creating complex patterns, signage, and prototypes.

Laser cutting offers several benefits when working with acrylic. Firstly, the process produces smooth, clean edges that often do not require further sanding or finishing, saving time and effort. Secondly, Laser Cutting is a fast process, allowing large quantities of acrylic to be cut in a short time, making it an efficient solution for both small and large-scale projects. Additionally, laser cutting produces minimal waste, as the thin laser beam can make precise cuts with minimal material loss. Finally, the versatility of Acrylic Laser Cutting Sydney means it can be used across various industries, from signage and displays to custom-made furniture and artistic installations.

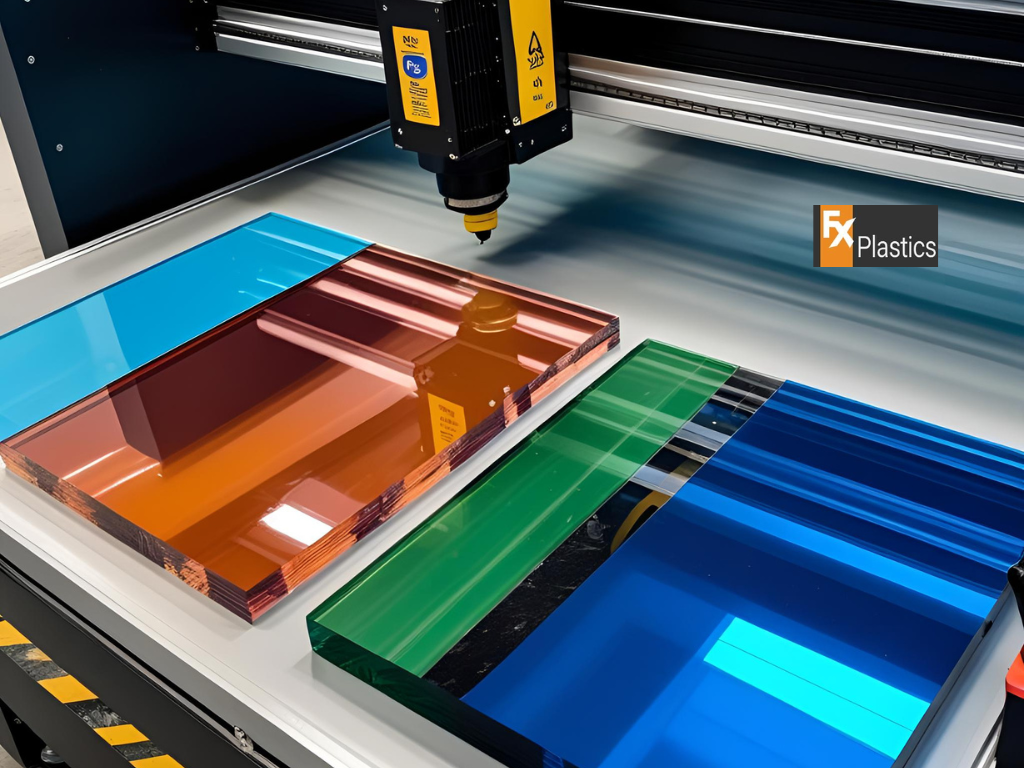

CNC Cutting (Computer Numerical Control) is a method that uses computer-controlled machines to cut materials. Unlike Laser Cutting, which uses a focused laser beam, CNC machines use physical tools such as drills or routers to cut through materials like acrylic. The CNC machine follows pre-programmed instructions to create the desired shapes or patterns. While CNC cutting is highly effective for thicker materials or projects requiring depth, it may not offer the same level of precision as laser cutting for thin acrylic sheets.

When comparing CNC Cutting to Laser Cutting, the primary difference lies in the tools and the precision. Laser Cutting is known for its high precision, particularly in thin materials like acrylic, allowing for fine details and smooth edges. In contrast, CNC Cutting is more suitable for thicker materials or where multiple layers of material need to be cut. However, CNC cutting may leave rougher edges and require additional finishing. For detailed designs, especially in creative and artistic projects, Acrylic Laser Cutting Sydney is often the preferred method due to its accuracy and ability to handle intricate patterns.

In Acrylic Laser Cutting Sydney, the versatility of laser cutting technology allows it to be applied across numerous industries. It is particularly popular in the signage industry, where precision and smooth edges are crucial for creating professional-grade signs and displays. In architecture, laser-cut acrylic panels are used for decorative features, partitions, and even custom lighting fixtures. The technology is also employed in retail for point-of-sale displays, packaging, and promotional materials, where accurate branding and design elements are essential.

Beyond industrial applications, Acrylic Laser Cutting Sydney is highly sought after for creative and artistic projects. Designers and artists use laser cutting to create unique pieces, such as wall art, jewellery, and bespoke furniture. Its precision allows for intricate patterns and delicate features that would be difficult to achieve with other cutting methods. From custom keychains and corporate gifts to large-scale sculptures, laser cutting opens up a wide range of possibilities for creative expression, making it the go-to solution for custom acrylic designs.

One of the most significant advantages of Laser Cutting over CNC Cutting is the level of precision it offers. Acrylic Laser Cutting Sydney provides unmatched accuracy, making it ideal for intricate designs and detailed cuts. The laser’s fine beam can cut through acrylic with exceptional precision, allowing for complex patterns, sharp edges, and smooth curves. This makes Laser Cutting perfect for applications like signage, artistic projects, and decorative features where detailed craftsmanship is essential. In contrast, CNC Cutting may struggle with the same level of intricacy, particularly in thin materials like acrylic.

Another key benefit of Laser Cutting is its ability to reduce material waste. Since the laser beam is extremely narrow, it removes only a small amount of material during the cutting process. This efficiency leads to less waste compared to CNC Cutting, which uses physical tools that often result in more material loss, especially with intricate designs. Additionally, Laser Cutting is generally faster, reducing production times and improving overall project efficiency. This makes it the preferred choice for projects that require minimal waste and a quick turnaround.

While Laser Cutting excels in precision and efficiency for thinner materials like acrylic sheets, CNC Cutting becomes more suitable when working with thicker materials. CNC Cutting uses mechanical tools that can handle deeper cuts, making it ideal for projects involving thicker acrylic or other materials. For example, in industrial applications where acrylic sheets are over a certain thickness, CNC Cutting may be the preferred option due to its ability to remove larger amounts of material without compromising the integrity of the cut.

CNC Cutting may also be more cost-effective for large-scale projects where fine detail is not the primary concern. For bulk production, such as manufacturing acrylic components in large quantities, CNC Cutting is often more efficient. Its ability to cut through thicker materials and handle repetitive tasks makes it ideal for large production runs, even if the precision is less critical than with Laser Cutting. In contrast, Acrylic Laser Cutting Sydney is more suited to smaller, intricate projects requiring high levels of detail.

The cost of Laser Cutting is influenced by several factors, including setup time, design complexity, and precision requirements. Acrylic Laser Cutting Sydney often requires careful preparation, especially for detailed designs, which can increase setup costs. However, once the machine is set up, laser cutting tends to be fast and efficient, particularly for intricate projects. Additionally, the precision offered by Laser Cutting often justifies its higher cost, especially for projects where aesthetics and detail are paramount, such as signage, artistic designs, and custom installations.

On the other hand, CNC Cutting may be more cost-effective for large-scale projects or when working with thicker materials. Since CNC Cutting is better suited for bulk production, it can reduce costs when cutting large volumes of acrylic components that don’t require intricate details. The mechanical nature of CNC Cutting means that while it may not achieve the same level of precision as laser cutting, it can still deliver consistent results at a lower cost per unit, making it ideal for high-volume production where speed and cost-efficiency are priorities.

When deciding between Acrylic Laser Cutting Sydney and CNC Cutting, it’s essential to evaluate the specific needs of your project. For projects that require high levels of precision, such as intricate patterns, custom signage, or decorative pieces, Laser Cutting is typically the better choice due to its accuracy and ability to produce clean, smooth edges. However, if your project involves thicker acrylic materials or large-scale production with less focus on intricate details, CNC Cutting may be more suitable.

To ensure the best results for your project, it’s always a good idea to consult with professionals who specialise in both Laser Cutting and CNC Cutting. By working with experts, you can receive guidance on the most appropriate cutting method based on your material, design complexity, and project requirements. Whether you choose Laser Cutting for its precision or CNC Cutting for its efficiency, consulting with experienced technicians will help ensure the right approach is taken to meet your project goals.

More Blog

Laser cut acrylic has become one of the most popular materials for custom projects. Its

Acrylic sheets are a go-to choice for many companies across Western Sydney. They are strong,

When it comes to choosing a perspex sheet sydney customers often ask the same question—should

More people and businesses are making eco-friendly choices these days, and the world of Design