When precision and design accuracy matter, cnc cutting services are a perfect solution. These services use advanced computer-controlled machines to create exact cuts on materials like metal, wood, and acrylic. Whether you’re in construction, design, or retail, having access to reliable cutting technology makes all the difference.

CNC, or Computer Numerical Control, ensures that every cut is clean, smooth, and identical to your design file. This level of precision is almost impossible to achieve by hand. For businesses, it means reduced waste, faster production, and better quality control.

Here are a few ways cnc cutting services support modern businesses:

It’s a smart investment for businesses that want to keep costs low while delivering top-quality results.

Traditional cutting methods depend heavily on manual skills, which can lead to small errors or uneven results. Cnc cutting services eliminate these issues by using pre-programmed software and digital blueprints to guide every movement of the machine.

The difference lies in precision. While manual cutting might vary from one piece to another, CNC systems maintain accuracy down to a fraction of a millimetre. That’s why industries like signage, fabrication, and furniture manufacturing rely heavily on them.

| Aspect | Manual Cutting | CNC Cutting Services |

|---|---|---|

| Accuracy | Depends on skill level | Digitally precise every time |

| Speed | Slower, requires labour | Faster and automated |

| Material Waste | Higher | Minimal waste |

| Complex Designs | Difficult to achieve | Easily handled through software |

In short, cnc cutting services give you repeatable results, no matter how detailed or complex your project is.

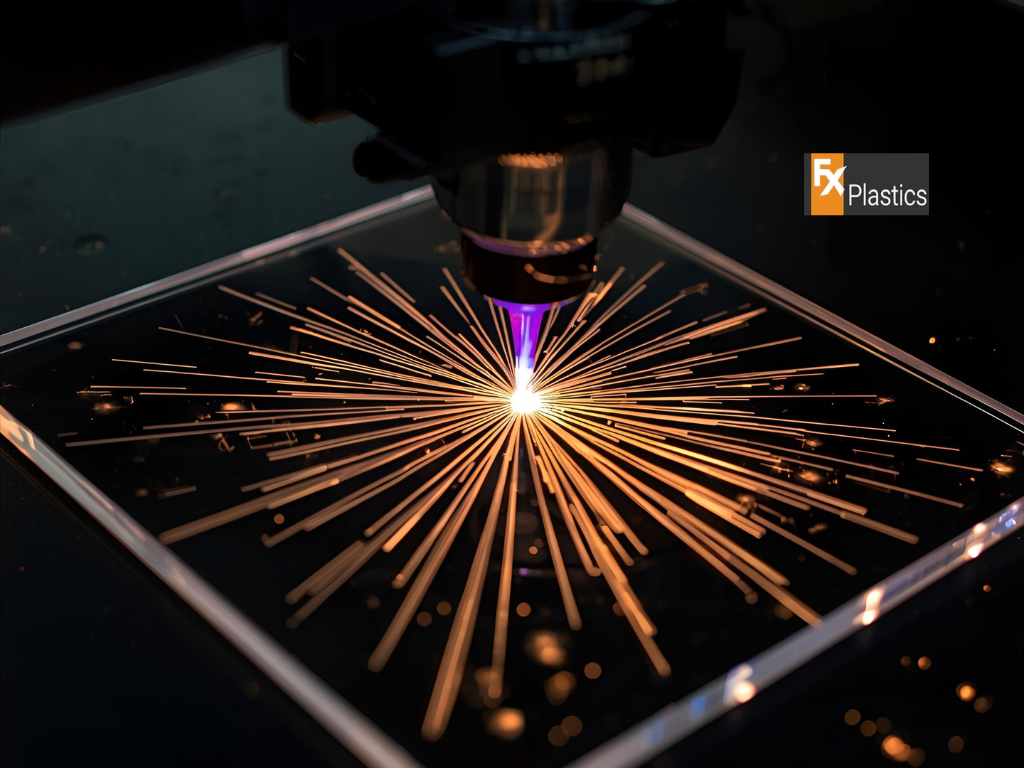

In creative and industrial settings, Acrylic Laser Cutting Sydney has become a go-to service for professionals who value detail and quality. Using laser technology, it can cut or engrave intricate designs with smooth, polished edges that don’t require additional finishing.

This process is perfect for acrylic signage, architectural models, and display units. The precision of laser cutting ensures that every edge is sharp and consistent, making it ideal for both artistic and functional applications.

Local businesses in Sydney often choose Acrylic Laser Cutting Sydney because it offers:

Whether it’s a one-off prototype or a full production run, laser cutting allows designers and manufacturers to turn digital designs into physical products quickly and affordably.

Acrylic Sheets sydney are among the most popular materials used across different industries today. Known for their strength, clarity, and lightweight nature, these sheets are perfect for both decorative and practical applications. From shop displays to architectural panels, they deliver durability with a clean, professional look.

When paired with cnc cutting services or Acrylic Laser Cutting Sydney, acrylic offers even more potential. The combination ensures perfect edges, clean cuts, and accurate sizing, which is critical for tight-fitting designs or complex layouts.

For designers, builders, and retailers, Acrylic Sheets sydney provide a creative and professional way to build modern structures, signage, and display systems.

Acrylic sheets have become one of the most versatile materials for modern fabrication. Their clear, glossy surface and durability make them a top choice for retail, interior design, and architectural projects. With the help of cnc cutting services, acrylic can be shaped into precise, creative forms without compromising strength or style.

From small decorative panels to full-sized commercial displays, Acrylic sheets are used in:

Each application benefits from precision cutting and high-quality finishing, which makes cnc cutting services an essential part of the process. Businesses in Sydney that rely on consistent quality often combine Acrylic Laser Cutting Sydney with CNC machining for both design flexibility and durability.

Since the demand for protective barriers has grown, retail perspex screens have become a staple in shops, offices, and service centres. These screens provide a layer of protection while keeping visibility and customer interaction smooth.

The key to an effective screen lies in its design precision. When created using cnc cutting services or Acrylic Laser Cutting Sydney, the screens fit perfectly into counters and fixtures. The clean, polished edges also enhance the overall look, making the installation both practical and attractive.

Benefits of precision-cut retail perspex screens:

In retail settings, a screen that looks good and functions well creates a welcoming and safe environment for both staff and customers.

Choosing the right company for cnc cutting services makes a huge difference in your final product’s quality and finish. The best service providers offer both technical skill and a strong understanding of design requirements.

When evaluating options, look for the following qualities:

A reliable cutting partner helps you bring your design ideas to life while ensuring each piece meets your expectations for accuracy, quality, and cost.

To make the most out of cnc cutting services, it helps to plan your project carefully and communicate clearly with your cutting provider.

Here are a few simple tips:

By following these steps, you’ll get better results and avoid costly revisions.

The world of cnc cutting services continues to evolve with technology. From laser systems to automated software, new tools are making fabrication faster and more precise than ever. In the near future, we can expect innovations that combine Acrylic Laser Cutting Sydney with AI-driven automation, helping businesses improve efficiency and product quality. This means more accurate cutting, reduced turnaround times, and even better finishes for complex designs.

For businesses working with Acrylic Sheets sydney, Acrylic sheets, or retail perspex screens, staying updated with cutting-edge technology ensures they maintain a competitive edge in both design and production.

More Blog

If you’re running a workshop, signage business, or custom build project in Western Sydney, precision

Supermarkets are busy places where customer interaction happens every few seconds. From checkout counters to

Modern businesses want materials that look good, last long, and offer creative flexibility. That’s why

When precision and design accuracy matter, cnc cutting services are a perfect solution. These services