What is CNC laser cutting?

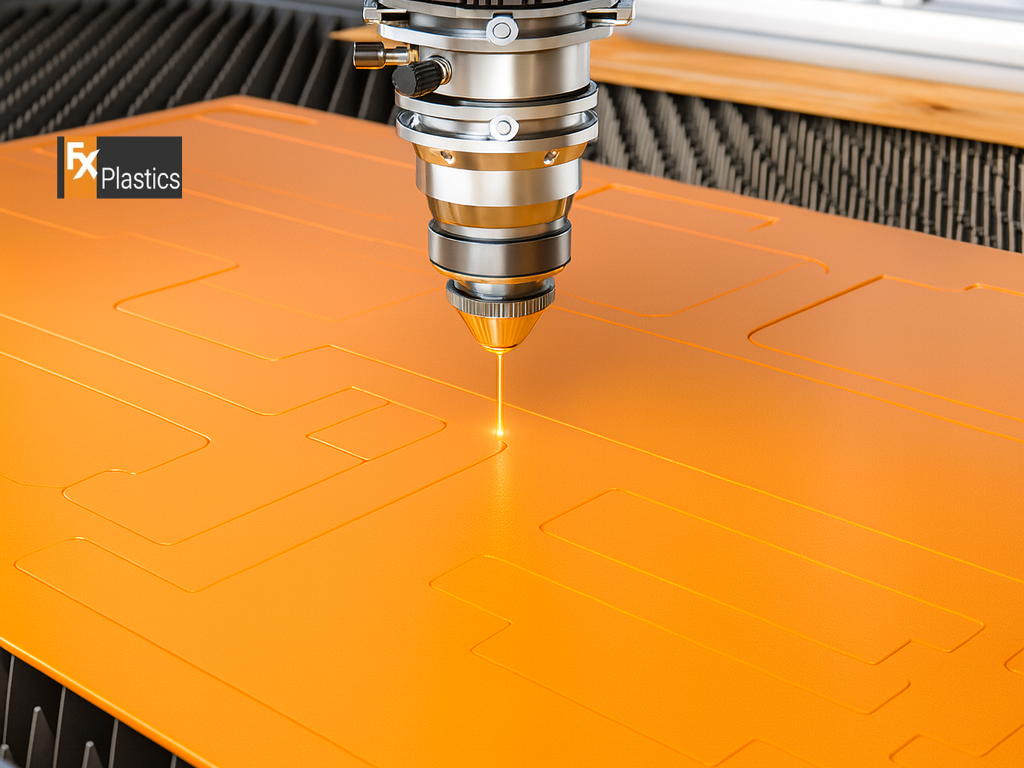

CNC laser cutting is a process of using a computer-controlled machine, which uses a laser beam to cut through materials.

CNC laser cutting is the most common type of laser cutting. It can be used for wood, plastics, metals and many other materials. It has gained popularity in the manufacturing industry because it can achieve high precision and accuracy while also being flexible in terms of materials that can be cut with it.

This guide will provide you with an overview of what CNC laser cutting is and how it works as well as some tips on how to choose the right company for your needs.

What are the Limitations of a CNC Laser Cutting Machine?

CNC laser cutting is a manufacturing process that uses a computer-controlled laser to cut through materials. It is used in industries such as aerospace, automotive, and electronics manufacturing. FX plastics is a company that specializes in the manufacturing of plastic products. They use a CNC laser cutting machine to cut and shape the plastic into different shapes.

CNC laser cutting offers numerous benefits for various industries. Firstly, it provides highly precise cuts, ensuring intricate designs can be achieved with ease. Additionally, it enables rapid production times, as the laser can process material at high speeds. This results in reduced scrap rates and costs, as there is less material waste. Lastly, CNC laser cutting improves product quality due to its increased accuracy and consistency in the cutting process.

Applications of CNC Laser Cutting

CNC laser cutting is utilized in a wide range of industries, such as aerospace, automotive, and electronics manufacturing. Some common applications include:

Choosing the Right CNC Laser Cutting Company

Selecting the appropriate CNC laser cutting company is crucial to ensure the success of your project. Consider the following factors when making your decision:

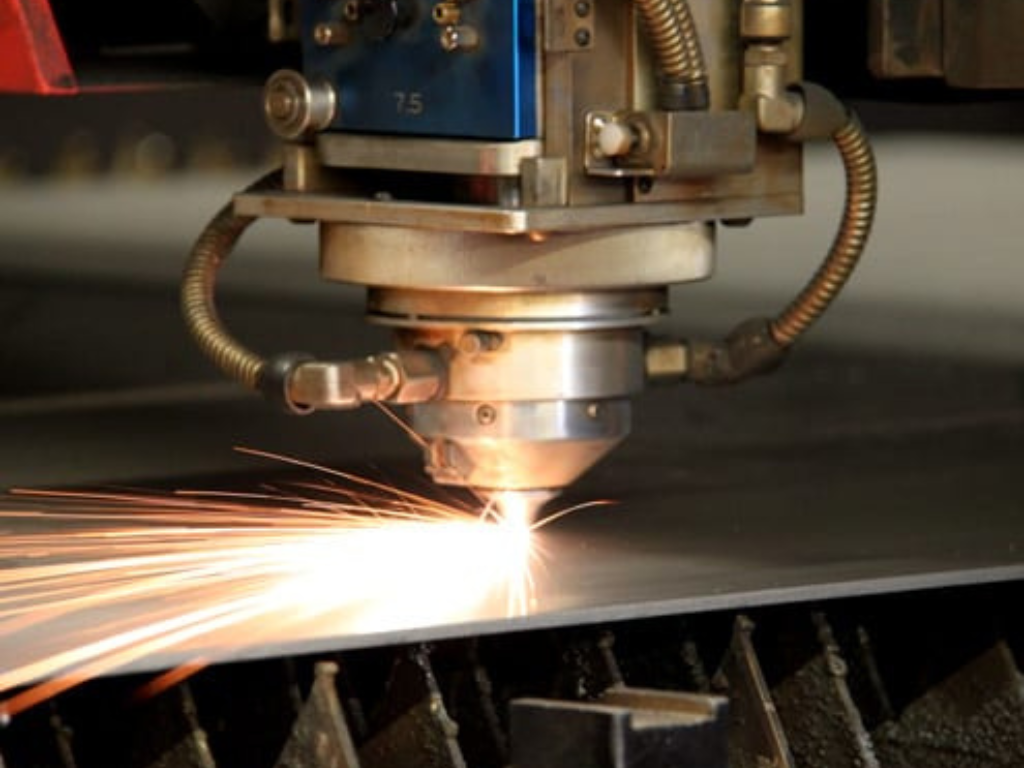

How Does a Metal Laser Cutter Work?

The metal laser cutter operates by focusing a high-powered laser beam onto the material’s surface, causing it to melt or vaporize. As the laser moves across the workpiece, it creates clean, precise cuts. CNC technology enables the laser cutter to achieve complex designs and high levels of accuracy, making it ideal for various applications across numerous industries.

There are several advantages to using a metal laser cutter, such as:

Revolutionize Your Productivity and Quality Control with a Metal Laser Cutter

CNC metal laser cutting machines offer numerous benefits, such as improved precision, increased efficiency, and reduced waste. By incorporating a metal laser cutter into your business from Fx Plastics, you can revolutionize your productivity and quality control, setting yourself apart from the competition. Consider investing in a metal laser cutter to enhance your manufacturing capabilities and elevate the quality of your products.

More Blog

Modern businesses want materials that look good, last long, and offer creative flexibility. That’s why

When precision and design accuracy matter, cnc cutting services are a perfect solution. These services

In recent years, more people have started to ask questions about the environmental impact of

When people hear Design and Fabrication, they often think of big metal structures. But in

30 Responses

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

ссылка на омгомг сайт [url=http://recoverleather.ru/]http://recoverleather.ru/[/url] .

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good. https://www.binance.com/cs/register?ref=S5H7X3LP

Thank you, your article surprised me, there is such an excellent point of view. Thank you for sharing, I learned a lot. https://www.binance.info/sl/join?ref=VDVEQ78S

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Your article helped me a lot, is there any more related content? Thanks!

Сервис доставки наборов для создания домашнего декора из

стекла и дерева.

My web page – essex university library colchester

Курсы по созданию контента для TikTok привлекают молодежь.

Медиа-стартап.

Here is my website сельский бизнес идеи

xrumer pro elite

– версия для профессионалов с расширенным функционалом.

Japan telegraph247 travel news news promotes domestic tourism amid restrictions.

detailing business cards ideas anniversary celebration ideas include gala events or charity drives.

Новости сегодняшние новости мира сегодня пестрят заголовками о новых технологиях и глобальных событиях.

Software to monitor computer engineer vs software engineer activity tracks usage, often for security or parental

control.

Flare luna crypto news

news focuses on its data interoperability solutions.

Coinpedia.org reports its growing role in DeFi ecosystems.

travel to mexico news nursing news

reports visa challenges for international healthcare workers.

The promo code for psychology today

Today subscription provides access to exclusive content and resources.

most beautiful photos of the world

bold sunflower stands tall with its radiant yellow petals.

Границы в психологии психология отношений цитаты защищают личное пространство.

کد تپ سواپ hot crypto news News

Flash delivers real-time updates on market trends and price movements.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me? https://www.binance.info/it/join?ref=S5H7X3LP

Your point of view caught my eye and was very interesting. Thanks. I have a question for you. https://www.binance.com/join?ref=P9L9FQKY

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Your article helped me a lot, is there any more related content? Thanks!

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.