When people hear Design and Fabrication, they often think of big metal structures. But in the world of acrylic, it’s all about precision, creativity, and clean finishes. Acrylic is a go-to material for businesses looking for a sleek, modern look without the heaviness of glass or metal. The process starts with an idea. Whether it’s for a protective acrylic screen, retail display, or custom signage, the concept is mapped out using digital tools.

From there, the material is selected, measurements are planned, and fabrication begins. Acrylic’s flexibility in design allows for endless applications. With the right tools, it can be cut, bent, polished, and shaped to fit almost any space.

Acrylic fabrication is a smart choice for many reasons. It’s lightweight, durable, and visually appealing. This makes it perfect for screens used in workplaces, retail, medical spaces, and hospitality settings.

Let’s look at a few reasons why acrylic stands out:

Easy to clean: A simple wipe-down keeps it clear and hygienic

Strong but light: It won’t shatter like glass and is easier to handle

Professional look: Adds a modern feel to any space

Highly customisable: Can be cut or bent into all kinds of shapes

When you need clear partitions or safety guards, an acrylic screen offers a simple yet effective solution. It blends into the background while still doing its job.

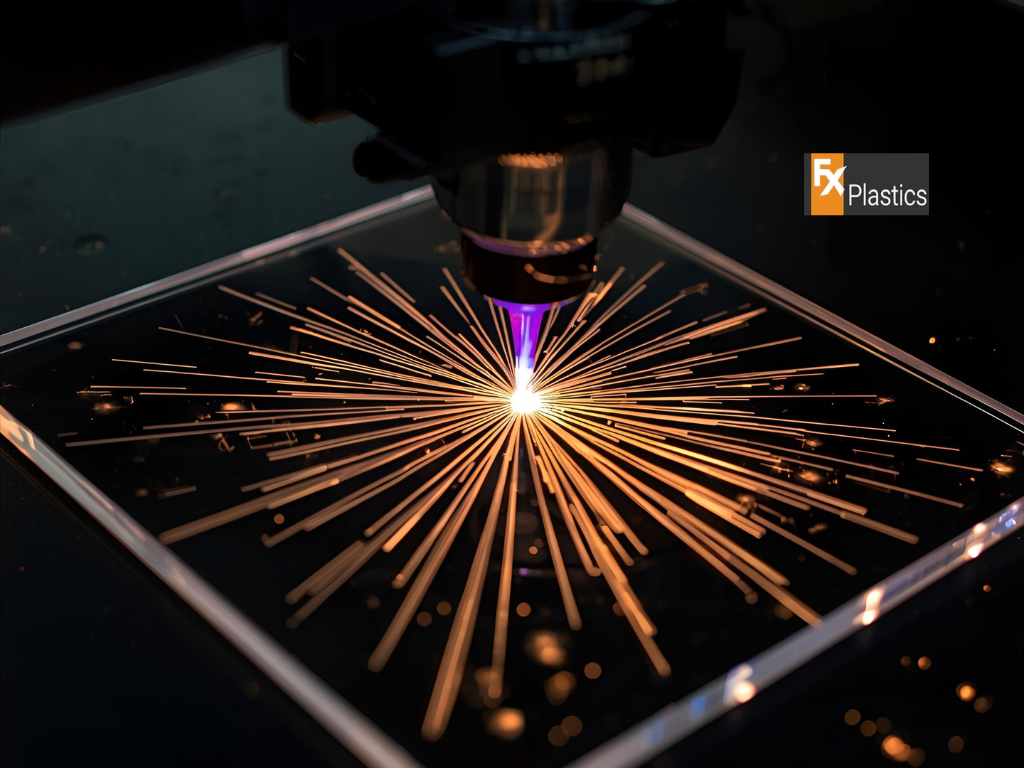

CNC stands for “Computer Numerical Control” and refers to machines that follow digital designs with extreme accuracy. With CNC laser cutting, acrylic sheets are cut to exact measurements without chips, cracks, or rough edges.

This method is perfect for Acrylic fabrication because:

It’s super precise

It works fast, even on large orders

The laser produces clean, polished edges

You get consistent quality with every cut

This is especially helpful when creating uniform items like office dividers or point-of-sale panels. The result is a polished finish that looks sharp and professional every time.

Acrylic screens are everywhere these days. They help maintain privacy, promote hygiene, and improve safety without compromising style.

Here are a few places where acrylic screen panels are most commonly used:

Offices – for workstations and meeting spaces

Retail counters – for customer service and checkout areas

Cafés and restaurants – to create spacing between diners

Events and exhibitions – for branding and crowd guidance

Schools and universities – dividing desks and lecture spaces

Because acrylic is clear and stylish, it works well in settings where you need both function and visual appeal.

One of the biggest advantages of acrylic is how easy it is to customise. With perspex cut to size, you can get panels that fit perfectly—whether it’s for a small countertop or a large workstation divider.

Here’s how cut-to-size perspex makes a difference:

No wasted material

Saves time during installation

Perfect fit every time

More professional results

Custom sizing ensures your acrylic screen fits neatly and does the job without making things look cluttered or mismatched. It also helps keep things cost-effective.

Traditional cutting methods like saws can be messy, loud, and inaccurate. But with laser cut acrylic, the process is smooth, silent, and highly precise.

Let’s compare the two quickly:

| Feature | Traditional Cutting | laser cut acrylic |

|---|---|---|

| Edge quality | Often rough | Smooth and clear |

| Accuracy | May vary | Very precise |

| Speed | Slower | Fast and efficient |

| Custom shapes | Limited | Highly flexible |

CNC laser cutting and laser cutting in general have made Acrylic fabrication faster, safer, and more advanced than ever before.

In the world of Design and Fabrication, acrylic continues to be a standout material. From creating hygienic acrylic screen solutions to custom signs and displays, it offers endless possibilities with style and durability. Whether you’re after perspex cut to size for a shop counter or need a custom shape using laser cut acrylic, the process has never been easier or more accessible.

With digital tools and precise cutting technology like CNC laser cutting, even small businesses can get professional results that last. Acrylic is more than just plastic—it’s a smart, flexible solution that suits all kinds of projects.

More Blog

If you’re running a workshop, signage business, or custom build project in Western Sydney, precision

Supermarkets are busy places where customer interaction happens every few seconds. From checkout counters to

Modern businesses want materials that look good, last long, and offer creative flexibility. That’s why

When precision and design accuracy matter, cnc cutting services are a perfect solution. These services