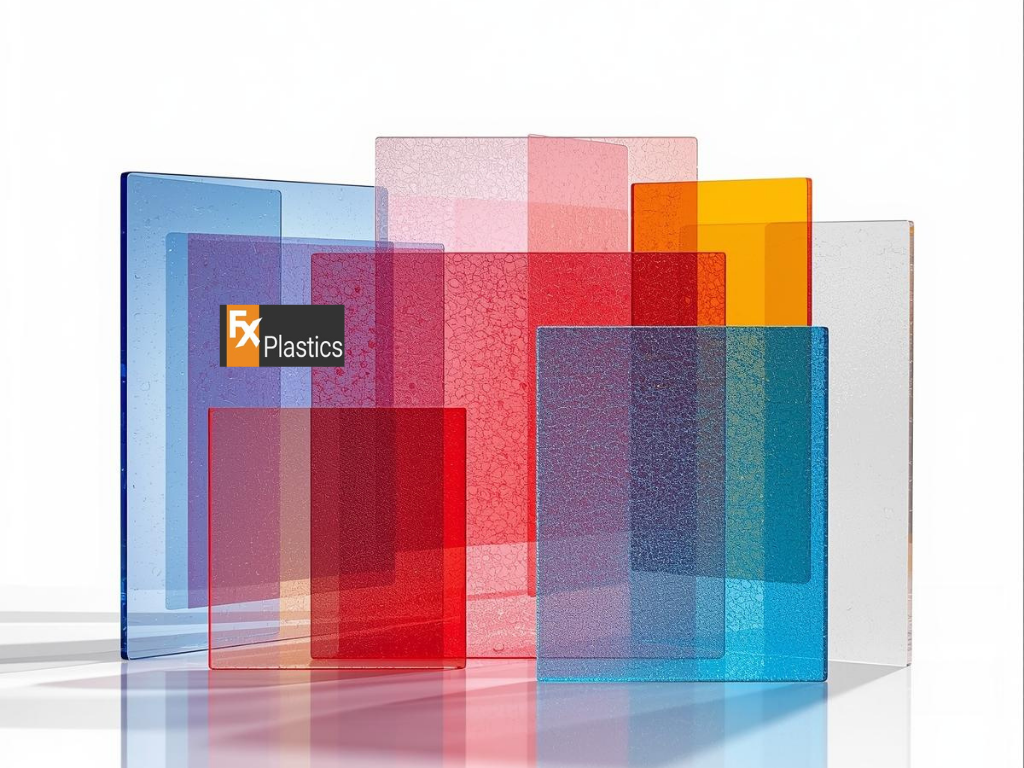

Acrylic sheets, often known by the brand names like Plexiglas or Lucite, are a versatile and clear plastic material resembling glass but offering greater impact resistance and durability. Due to their clarity, weather resistance, and high strength, acrylic sheets are widely used in various applications ranging from signage and displays to windows and protective barriers.

Importance of Proper Handling and Preparation

Handling and preparing acrylic sheets properly is crucial to avoid damage such as scratches, cracks, and deformations. Proper preparation ensures that the acrylic sheets maintain their aesthetic qualities and perform well for their intended use, particularly in delicate applications like plastic display where visual clarity and precision are paramount.

Different Types of Saws Suitable for Acrylic Sheets

Cutting acrylic sheets can be done with several types of saws, depending on the thickness of the material and the type of cut required:

- Table Saws: Best for making straight cuts on thicker sheets of acrylic.

- Jigsaws: Ideal for cutting intricate shapes and curves.

- Band Saws: Effective for cutting thick sheets and detailed shapes without inducing stress on the material.

- Manual Tools: For thinner acrylic sheets or small projects, simple hand tools like scoring tools can be effective. They allow for more control and are sufficient for scoring the acrylic, which can then be snapped along the scored line.

- Power Tools: For thicker sheets or larger projects, power saws with blades designed for cutting acrylic should be used. These tools save time and effort on extensive cutting tasks and help maintain precision and cleanliness of the cut edges.

Preparing Acrylic Sheets for Cutting

Safety Precautions and Protective Gear

Safety is paramount when working with acrylic sheets. Always wear safety goggles to protect your eyes from flying particles. Using gloves can help protect your hands from sharp edges and the heat generated from power tools. Additionally, working in a well-ventilated area is crucial when using power tools to minimize the inhalation of dust.

Measuring and Marking Acrylic Sheets Accurately

Accurate measurement and marking are essential for achieving precise cuts, especially when the acrylic sheets are intended for use in plastic displays:

- Measuring: Use a tape measure or ruler to measure the size needed. Always double-check measurements before cutting.

- Marking: Mark the cut lines with a grease pencil or non-permanent marker, which provides visibility and can be easily cleaned off after cutting.

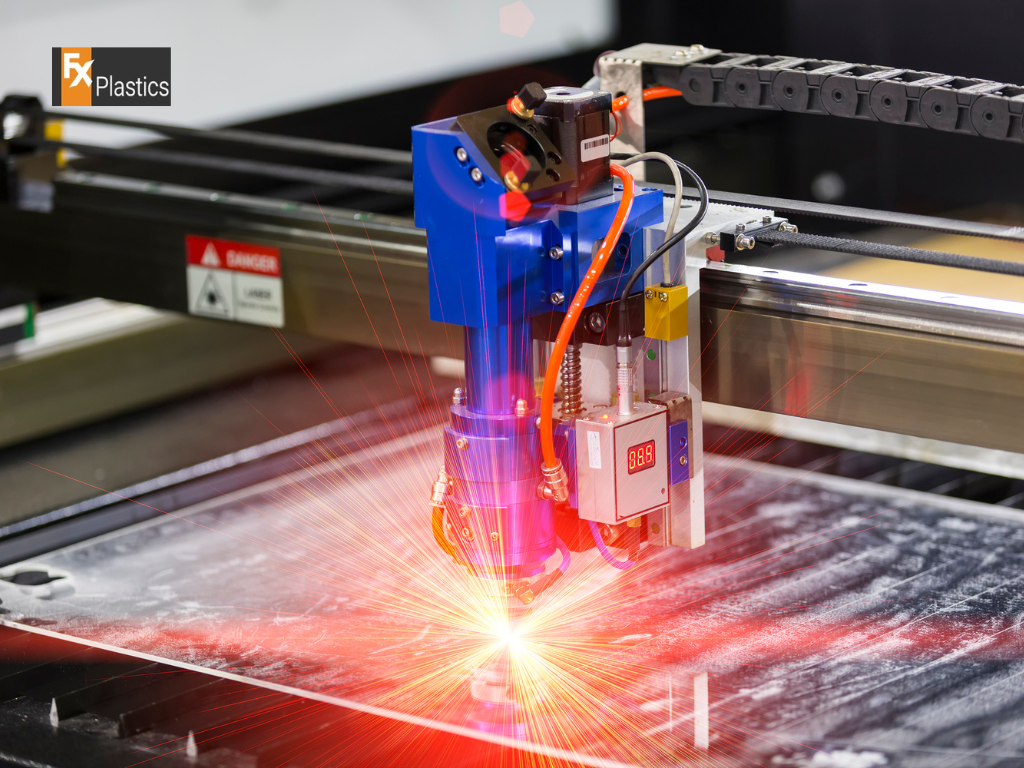

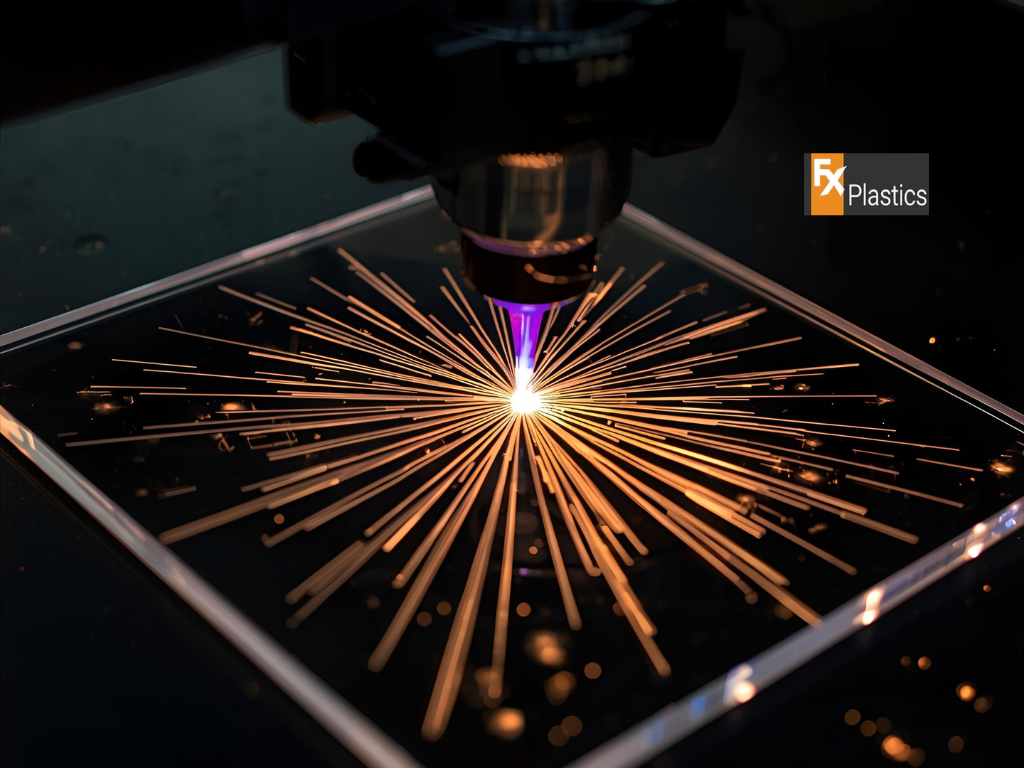

Cutting Techniques for Acrylic Sheets

How to Use a Jigsaw for Curved Cuts

Using a jigsaw is ideal for making curved cuts on acrylic sheets:

- Blade Selection: Choose a blade with fine teeth to reduce the risk of chipping.

- Speed Settings: Operate the jigsaw at a medium speed to avoid melting the acrylic with excessive heat from the blade.

- Support the Sheet: Ensure the acrylic sheet is well-supported near the cut line to prevent vibrations and breakage.

Best Practices for Straight Cuts Using a Table Saw or Circular Saw

For straight, clean cuts, using a table saw or circular saw is recommended:

- Blade Type: Use a blade designed for cutting plastic, which typically has more teeth for a smoother cut.

- Feed Rate: Feed the acrylic sheet slowly into the saw to prevent the blade from overheating and melting the material.

- Support the Acrylic: Use clamps or a push stick to securely feed the acrylic through the saw without putting your hands near the blade.

Tips for Preventing Cracks and Chips During Cutting

- Protective Film: Keep the protective film on the acrylic sheet while cutting to reduce scratches.

- Proper Blade: Ensure the saw blade is sharp and appropriate for acrylic to minimize chipping.

- Cutting Technique: Do not force the sheet through the saw; let the blade do the work at its own pace.

Shaping Acrylic Sheets for Plastic Displays

Techniques for Bending and Molding Acrylic Sheets

- Heating: Use a strip heater or an oven to evenly heat the acrylic until it becomes flexible.

- Molding: Once heated, quickly mold the acrylic over a form or jig before it cools and hardens.

Using Heat Guns and Strip Heaters for Shaping

- Heat Guns: Ideal for small, local bends or complex curves.

- Strip Heaters: Best for making straight-line bends across the width of the sheet.

Creating Complex Shapes and Contours

- Forming Techniques: Use vacuum forming or drape molding for more complex shapes.

- Cooling: Allow the acrylic to cool slowly in the mold to avoid introducing stress that could lead to warping or cracking.

Finishing Edges and Polishing Acrylic Sheets

Sanding Techniques for Smooth Edges

- Gradual Sanding: Start with a coarser grit sandpaper and progressively work your way to finer grits.

- Wet Sanding: Use wet sanding techniques for the final stages to achieve a smooth, flawless edge.

Polishing Methods to Achieve a Glossy Finish

- Buffing: Use a buffing wheel with a polishing compound designed for acrylics.

- Flame Polishing: Carefully apply a flame to the edge of the acrylic to melt and smooth the surface, resulting in a glossy finish.

- Sanding Blocks: For even pressure distribution during sanding.

- Polishing Compounds: Specifically formulated for acrylic materials.

- Buffing Wheels: Attach to a drill or rotary tool for high-speed polishing.

Common Mistakes to Avoid When Working with Acrylic Sheets

Overheating Risks and How to Avoid Them

Acrylic sheets are prone to melting or warping when exposed to high temperatures during cutting or shaping:

- Use the Correct Blade Speed: When using power tools, adjust the speed to prevent the blade from getting too hot, which can melt the acrylic.

- Proper Tooling: Ensure your tools are suitable for acrylic; for example, use saw blades with more teeth for a smoother and cooler cut.

- Pause Frequently: Allow the acrylic and the tool to cool down periodically during intensive cutting or shaping.

Avoiding Scratches During Cutting and Shaping

Scratches are a common issue when working with acrylic due to its soft surface:

- Keep Protective Film On: Maintain the original protective film on the acrylic sheets as long as possible during the fabrication process.

- Clean Work Area: Ensure that the work surface and tools are free of debris that could scratch the acrylic.

- Use Soft Jaws in Clamps: When clamping acrylic, use clamps with rubber or soft jaws to avoid marking the surface.

Ensuring Clean and Clear Cuts Without Cracking

Achieving a clean cut without cracking the acrylic can be challenging but can be managed with careful handling:

- Do Not Force the Material: Let the tool do the work at a consistent feed rate to reduce stress on the acrylic.

- Support the Sheet: Provide adequate support close to the cut to minimize vibrations and the chance of cracking.

- Score and Snap for Thin Sheets: For thin sheets, use a scoring method followed by snapping for a cleaner cut.

Best Practices for Achieving Professional Results

Recap of Key Techniques for Cutting and Shaping Acrylic Sheets

To summarize, successful cutting and shaping of acrylic sheets involve:

- Selecting the right tools and settings for each job.

- Handling the material carefully to avoid heat build-up and physical damage.

- Supporting and securing the acrylic properly during all operations.

Final Tips for Maintaining Quality in Plastic Displays

- Regular Inspection: Regularly check your tools and equipment for wear and ensure they are clean and properly adjusted.

- Test Cuts: Always make a test cut on a scrap piece of acrylic to check the setup and adjust if necessary before proceeding with the final piece.

- Quality Control: Examine the acrylic closely after each process step for any signs of damage or imperfection.

Encouragement to Experiment and Learn Through Practice

Working with acrylic is as much an art as it is a science. Encourage experimentation:

- Try New Techniques: Experiment with different techniques and tools to find what works best for your specific application.

- Learn from Mistakes: Each error provides a valuable learning opportunity to improve your skills.

- Seek Advice and Continue Learning: Engage with other professionals, join forums, and attend workshops to stay updated with the latest techniques and tools.