Plastic fabrication is the process of designing, manufacturing, and assembling plastic products and components. This versatile method is used across a variety of industries, including construction, automotive, aerospace, medical, and retail. Plastic fabricators Sydney leverage advanced techniques such as CNC machining, laser cutting, thermoforming, and welding to create custom plastic parts and structures tailored to specific needs.

Importance of Material Selection in Plastic Fabrication

Selecting the right material is crucial in plastic fabrication as it directly impacts the functionality, durability, and aesthetics of the final product. Different plastics offer unique properties that make them suitable for various applications. The right choice ensures that the product meets the required standards and performs effectively in its intended environment. Factors such as strength, flexibility, transparency, and resistance to environmental conditions must be considered when choosing the material.

Common Plastics Used in Fabrication

Properties and Uses of Perspex

Perspex sydney, also known as acrylic, is a popular choice in plastic fabrication due to its excellent clarity, light weight, and resistance to UV light and weathering. It is often used in applications where transparency and durability are essential, such as signage, display cases, and protective barriers. Perspex is also easy to cut, shape, and polish, making it ideal for custom designs.

Advantages of Using Perspex Sheets in Sydney

Using Perspex sheets in Sydney offers several benefits:

- High Transparency: Perspex provides excellent optical clarity, making it a preferred material for displays and windows.

- Weather Resistance: It withstands harsh weather conditions, ensuring longevity in outdoor applications.

- Lightweight: Perspex is lighter than glass, making it easier to handle and install.

- Customization: Available in various colors and finishes, Perspex sheets can be tailored to specific design requirements.

Specialty Plastics for Advanced Applications

For applications requiring superior performance, specialty plastics like polycarbonate and PTFE (Teflon) are used. Polycarbonate is known for its high impact resistance, making it suitable for protective gear, machine guards, and automotive parts. PTFE, on the other hand, offers exceptional chemical resistance and a low friction coefficient, making it ideal for seals, gaskets, and non-stick coatings.

Applications of Specialty Plastics in Various Industries

- Polycarbonate: Used in security windows, eyewear lenses, and medical devices due to its strength and clarity.

- PTFE: Commonly used in chemical processing, food industry, and aerospace for its non-reactive and heat-resistant properties.

- Nylon: Preferred in mechanical components like gears and bearings for its wear resistance and high mechanical strength.

Choosing the Right Material for Your Project

Factors to Consider: Durability, Transparency, Flexibility

When selecting a material for your plastic fabrication project, consider the following factors:

- Durability: Assess the material’s ability to withstand environmental stress, wear and tear, and chemical exposure.

- Transparency: For applications requiring clear visibility, materials like Perspex or polycarbonate are ideal.

- Flexibility: Depending on the application, you may need a material that can be easily molded or bent without breaking.

Comparing Different Types of Plastic Sheets for Optimal Results

To achieve the best results for your project, compare the properties of various plastic sheets:

- Perspex vs. Polycarbonate: While both offer high clarity, polycarbonate is more impact-resistant but less scratch-resistant than Perspex.

- PTFE vs. Nylon: PTFE is superior for chemical resistance and high-temperature applications, whereas nylon offers better mechanical strength and wear resistance.

- PVC vs. Acrylic: PVC is more cost-effective and suitable for large-scale applications, whereas acrylic provides better optical properties and design flexibility.

Benefits of Using Perspex for Plastic Fabrication

Aesthetic and Functional Advantages of Perspex

Perspex, also known as acrylic, offers several aesthetic and functional advantages that make it a preferred material in plastic fabrication:

- Clarity and Transparency: Perspex provides excellent optical clarity, making it ideal for applications where transparency is crucial, such as display cases, windows, and protective barriers.

- Lightweight: Perspex is significantly lighter than glass, which simplifies transportation, handling, and installation processes.

- Durability: It has a high resistance to impact and weathering, ensuring longevity in both indoor and outdoor applications.

- Versatility: Perspex can be easily cut, shaped, and polished, allowing for a wide range of custom designs and applications.

- Color Options: Available in various colors and finishes, Perspex can be tailored to meet specific design and branding requirements.

Common Applications of Perspex Sheets in Sydney

In Sydney, Perspex sheets are widely used in numerous applications:

- Signage and Displays: Businesses use Perspex for creating eye-catching signs and displays due to its clarity and ease of customization.

- Architectural Features: Perspex is employed in architectural projects for windows, skylights, and decorative elements.

- Protective Barriers: Especially relevant in recent times, Perspex is used to create protective screens and barriers in offices, retail stores, and public spaces.

- Furniture and Decor: Designers use Perspex to create modern furniture pieces and decorative items, taking advantage of its aesthetic appeal and versatility.

Environmental Impact and Sustainability of Plastic Materials

Sustainable Practices in Plastic Fabrication

Plastic fabrication can incorporate several sustainable practices to minimize environmental impact:

- Efficient Material Usage: Reducing waste through precise cutting and optimization techniques.

- Sustainable Sourcing: Choosing materials from suppliers that adhere to sustainable and ethical practices.

- Energy-Efficient Processes: Implementing energy-saving technologies and practices in the fabrication process to reduce carbon footprint.

Recycling and Waste Management of Perspex and Other Plastics

Effective recycling and waste management are crucial for sustainability:

- Recycling Programs: Participating in or establishing recycling programs to repurpose waste materials and reduce landfill contributions.

- Waste Reduction: Implementing practices that minimize offcuts and scraps, such as precision cutting and using reusable molds.

- Recycling Perspex: Perspex is fully recyclable and can be reprocessed into new products, reducing the need for virgin materials and decreasing environmental impact.

Working with Plastic Fabricators in Sydney

Finding Reliable Plastic Fabricators in Sydney

To ensure high-quality results, it’s important to find reliable plastic fabricators Sydney:

- Research and Reviews: Look for fabricators with positive customer reviews and a strong reputation for quality work.

- Portfolio and Experience: Choose fabricators with extensive experience and a diverse portfolio showcasing their capabilities in various projects.

- Certifications and Standards: Ensure the fabricator adheres to industry standards and holds relevant certifications for quality and safety.

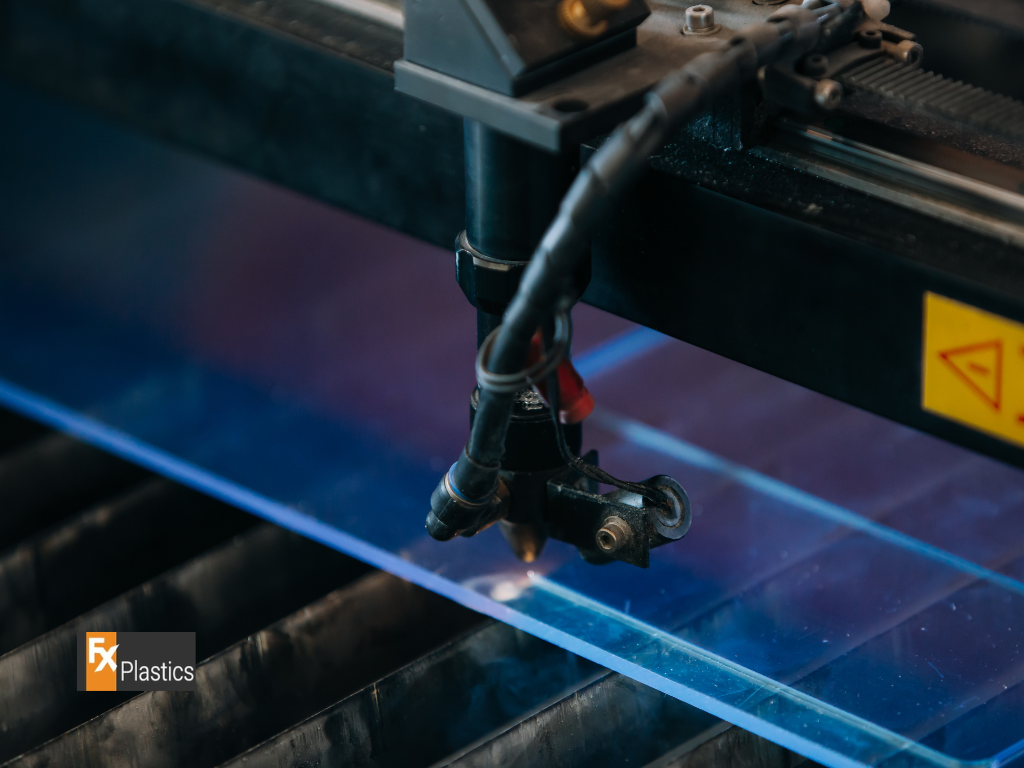

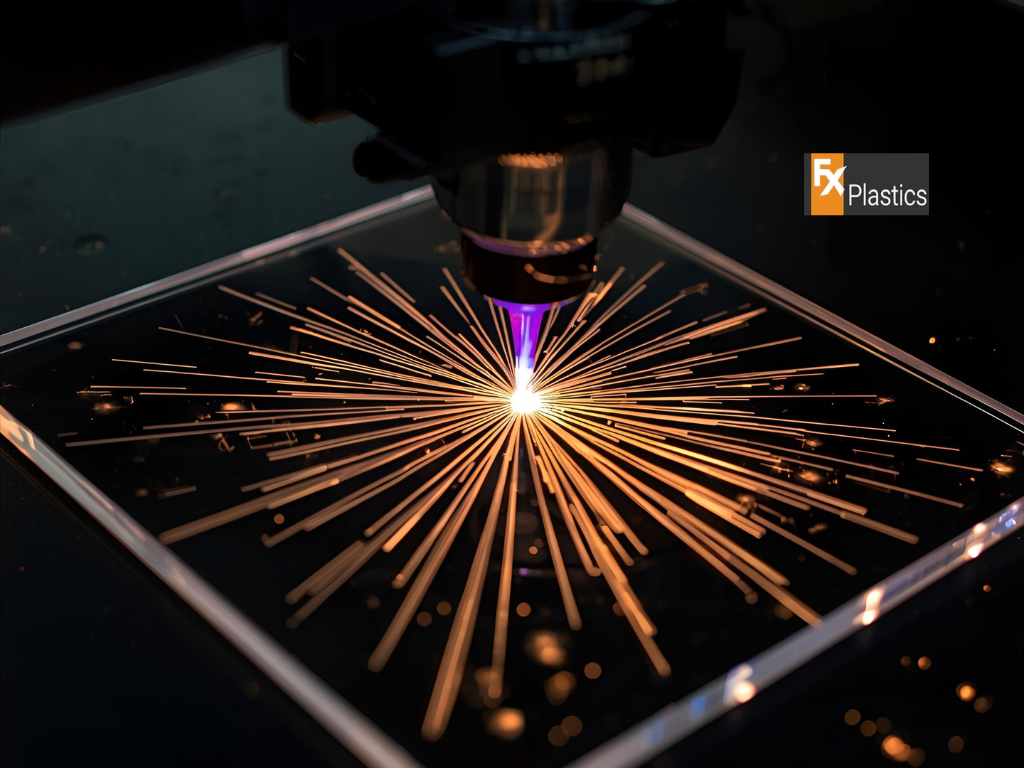

Services Offered by Plastic Fabricators: Customization, Cutting, Shaping

Plastic fabricators in Sydney offer a range of services to meet diverse needs:

- Customization: Tailoring plastic products to specific designs, sizes, and functional requirements.

- Cutting and Shaping: Using advanced techniques like CNC machining, laser cutting, and thermoforming to achieve precise shapes and dimensions.

- Assembly and Finishing: Providing additional services such as welding, bonding, and surface finishing to complete the product.

Innovations in Plastic Fabrication Materials

New Developments in Plastic Materials

The field of plastic fabrication is constantly evolving with new material developments:

- Biodegradable Plastics: Innovations in biodegradable plastics offer eco-friendly alternatives for various applications.

- High-Performance Composites: The development of composites that combine plastics with other materials to enhance properties like strength, durability, and thermal resistance.

Future Trends in Plastic Fabrication Technology

Future trends in plastic fabrication technology include:

- 3D Printing: Advancements in 3D printing technology are allowing for more complex and customizable plastic products with reduced waste.

- Automation and AI: The integration of automation and artificial intelligence in fabrication processes to improve precision, efficiency, and scalability.

- Smart Materials: The development of smart plastics that can change properties in response to environmental conditions or stimuli, opening new possibilities in various industries.