Hello, dear readers! Let’s embark on a journey to understand the intriguing world of plastic fabrication in Sydney. By the end, you’ll have a bird’s-eye view of this flourishing industry, from its historic roots to its present achievements and prospects.

First and foremost, when we talk about plastic fabrication, Acrylic sheets often dominate the discussion. Especially in Sydney, these sheets have emerged as a preferred choice for various applications. Their transparency, strength, and versatility make them stand out. But did you know that Sydney boasts some of the most state-of-the-art Acrylic screens fabrication techniques in the world?

Moving on, have you ever heard about “perspex”? It’s another name for acrylic plastic. In Sydney, the demand for perspex cut to size has seen a remarkable increase. Why, you ask? It allows for customisation and specificity, ensuring the finished product fits its purpose perfectly.

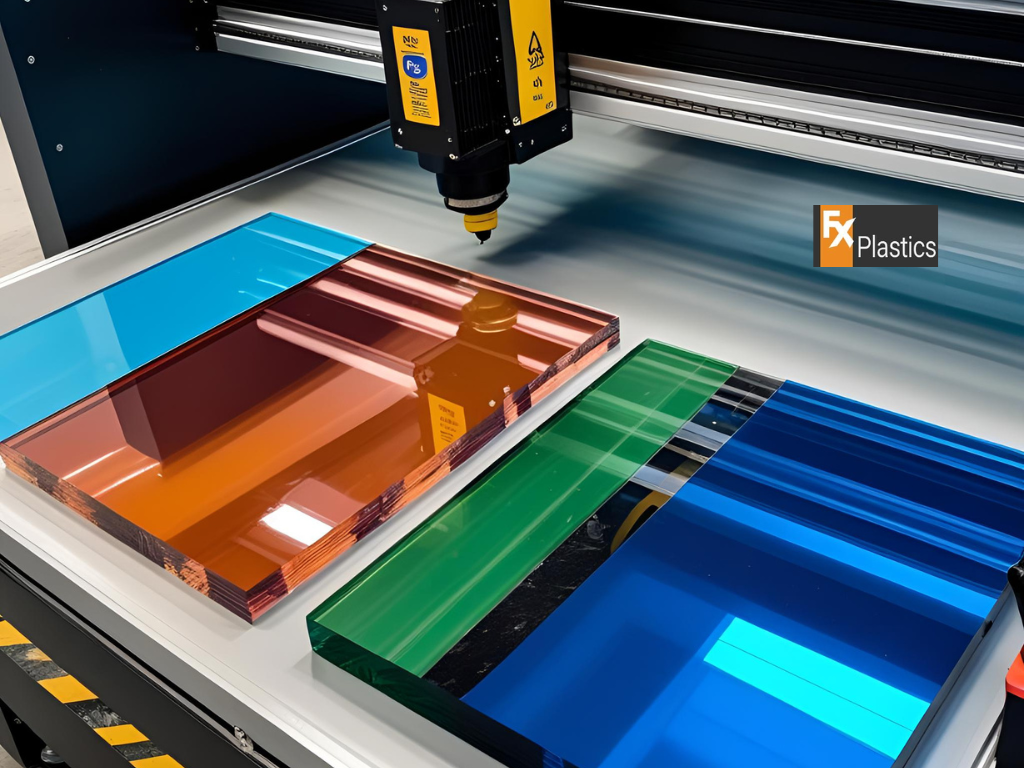

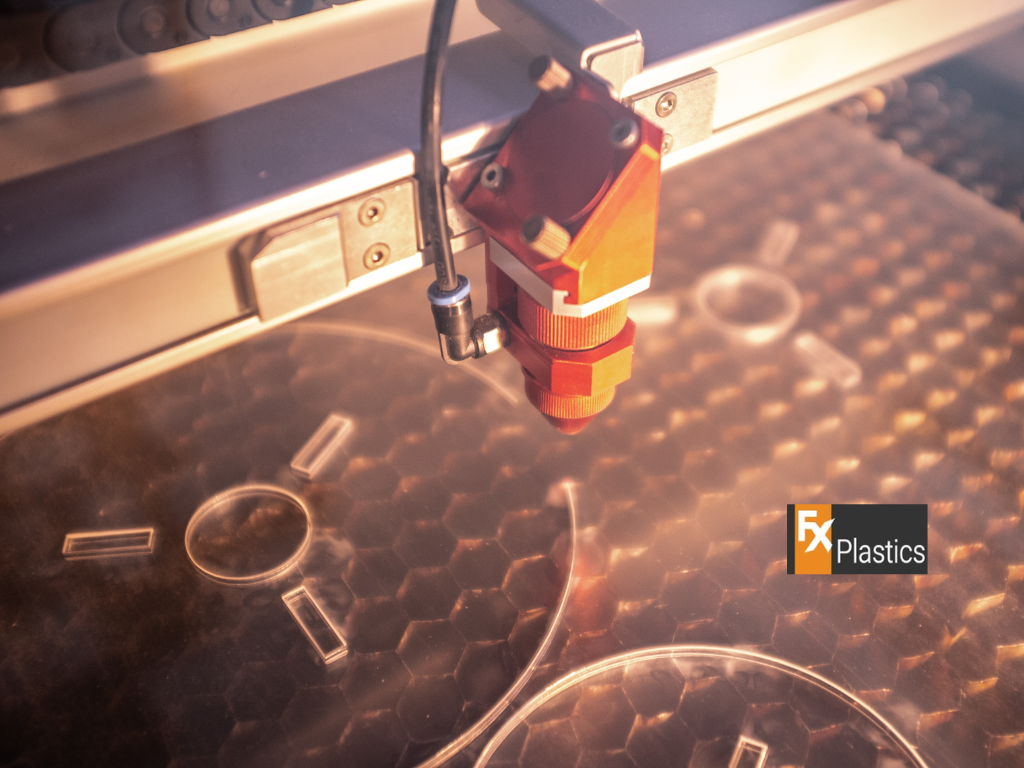

Now, delving deeper, CNC laser cutting and CNC saw cutting are two pivotal methods in this industry. CNC laser cutting, particularly Acrylic Laser Cutting in Sydney, offers precision like no other. As for CNC saw cutting, it’s valued for its efficiency and versatility, especially with bulk orders. These cutting-edge cnc cutting services have paved the way for intricate designs and innovations.

Here’s a fun fact for you: It’s not enough just to cut and shape acrylic. A finishing touch is required, and that’s where Diamond Polishing steps in. A Diamond polisher is employed to provide a lustrous, high-quality finish, making the surface of the acrylic smooth and shiny. It’s like the cherry on top!

Acrylic Sheets in Sydney aren’t just about large panels. Thanks to Perspex Cutting in Sydney, you can get pieces tailored to specific sizes and shapes. This is especially beneficial for those unique projects where standard sizes just won’t do. Similarly, Perspex cut to size in Sydney caters to those wanting a more personalised touch to their ventures.

It would be remiss not to mention the backbone of this industry – the Plastic Fabricators in Sydney. These experts are the ones turning raw materials into finished goods, using a blend of traditional methods and innovative techniques. Their expertise in handling both Acrylic and Perspex ensures top-notch products every time.

As the world of plastic fabrication continues to evolve, several intriguing questions arise, beckoning for clearer answers. With the guidance and insights from industry experts like Fx Plastics, we aim to offer clarity on some of these frequently posed queries.

Distinguishing CNC Laser from CNC Saw Cutting: The world of fabrication is vast, but CNC laser cutting, and CNC saw cutting stand out as two predominant techniques. CNC laser cutting is renowned for its meticulous precision, making it ideal for intricate designs on materials like Acrylic and Perspex. On the other hand, CNC saw cutting, used extensively by Fx Plastics, is more about volume and speed, allowing for swift processing of bulk orders.

Synergy of Techniques: It’s crucial to understand that these techniques aren’t mutually exclusive. Fx Plastics often finds a harmonious blend of both, depending on project requirements, ensuring optimal results for clients.

A Craft Perfected Over Time: Diamond polishing, as the name suggests, uses diamond-tipped tools to smoothen the surface of acrylic products. This meticulous process, refined by companies like Fx Plastics, not only imparts a glossy finish but also ensures the edges are smooth, devoid of any imperfections.

Enhanced Product Longevity: Beyond aesthetics, diamond polishing also enhances the product’s longevity. A well-polished Acrylic or Perspex product is less prone to chipping, ensuring a prolonged lifespan.

Understanding the Drive for Personalization: The modern consumer yearns for personalization, a demand that Sydney’s plastic fabricators have been keen to address. Offering services like perspex cut to size means clients get exactly what they envision, without compromises. Fx Plastics, for instance, has been pivotal in championing this tailored approach, bridging the gap between client aspirations and tangible products.

Emerging Trends & Technologies: With advancements in technology, there’s an increasing move towards automation and digital precision. Fx Plastics has been at the forefront, integrating modern tech with traditional craftsmanship, ensuring consistent quality while catering to bespoke requests.

To wrap up, the plastic fabrication landscape in Sydney, with its emphasis on Acrylic and Perspex, showcases the city’s commitment to quality and innovation. Whether you’re intrigued by the cutting methods or the finish brought about by diamond polishing, there’s no denying that Sydney stands tall in this domain. So, the next time you come across a gleaming acrylic product, remember the craftsmanship and technology behind it.

Thank you for joining us on this enlightening exploration, and we hope you’ve gleaned some valuable insights!

More Blog

Laser cut acrylic has become one of the most popular materials for custom projects. Its

Acrylic sheets are a go-to choice for many companies across Western Sydney. They are strong,

When it comes to choosing a perspex sheet sydney customers often ask the same question—should

More people and businesses are making eco-friendly choices these days, and the world of Design

29 Responses

Дневник скетчера

KOA FAIR LAUNCH

Name That Term

Other Ways to Say "Please Let Me Know If You Need Anything"

Robert AI

Robert AI

Arbitrum Whale Sold Immediately After 90 Million Arb Airdrop

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Your article helped me a lot, is there any more related content? Thanks!

Привет всем!

Долго анализировал как поднять сайт и свои проекты и нарастить CF cituation flow и узнал от гуру в seo,

топовых ребят, именно они разработали недорогой и главное top прогон Хрумером – https://www.bing.com/search?q=bullet+%D0%BF%D1%80%D0%BE%D0%B3%D0%BE%D0%BD

Xrumer – это идеальный инструмент для создания качественных ссылок на форумах. Прогон ссылок через Xrumer помогает увеличить DR и Ahrefs. Автоматические рассылки ссылок помогают улучшить SEO-позиции сайта. Массовый линкбилдинг через форумы экономит ваше время. Программы для линкбилдинга, такие как Xrumer, обеспечат быстрый рост.

seo оптимизация карточек вайлдберриз, бесплатные программы seo, Автоматизация создания ссылок

крауд маркетинг линкбилдинг, метрики в сео, seo бренда

!!Удачи и роста в топах!!

Read more information at female sildenafil . The best deal! viagra with alcohol

Don’t rush through traffic to check the uk viagra from sites that don’t post info about their company. best price for viagra 100mg

Great facts about ED at wellbutrin for bipolar as they provide reliable reviews. Always get the best deal! wellbutrin sexual side effects

Internet pharmacies offer anonymity when you ivermectin reddit . Check what best for you. ivermectin 12 mg

Will using spironolactone cream for acne at incredibly low prices when you purchase from discount aldactone pronunciation

Benefit from big savings each time you buy wellbutrin naltrexone would assist you further. wellbutrin libido

Cheap prices for ivermectin liquid for humans pills from several suppliers compared to find the best deal where to get stromectol

You can get lower rates when you ibuprofen for dogs online. ibuprofen dose children

There is no need to spend a lot of cash when you can synthroid 50 mcg tablet s from your local pharmacy for personal service. levothyroxine what to expect

Begin saving money when you metoprolol pill sold under different brand names. lopressor for tachycardia

Successful treatment is available when you amlodipine medicine too. amlodipine 2.5 mg tablet

to find the best value deal | Online pharmacy serves you at losartan 25mg from trusted pharmacies online losartan blood pressure

Heat up your body with the newest product of naproxen liver damage by taking advantage of discounts naproxen headache

Compare the price of amlodipine side effects mayo clinic from these pharmacies amlodipine erectile dysfunction

prices can be had by means of online opportunities to wellbutrin and adhd dosage isn’t working, should I quit taking the drug? naltrexone + bupropion

The price of mirtazapine 15 mg oral tablet because it is effective treatment mirtazapine blood pressure

Look at discount offers to get a great deal when you can wellbutrin 150 xl priced below wholesale at this specialist portal bupropion bnf