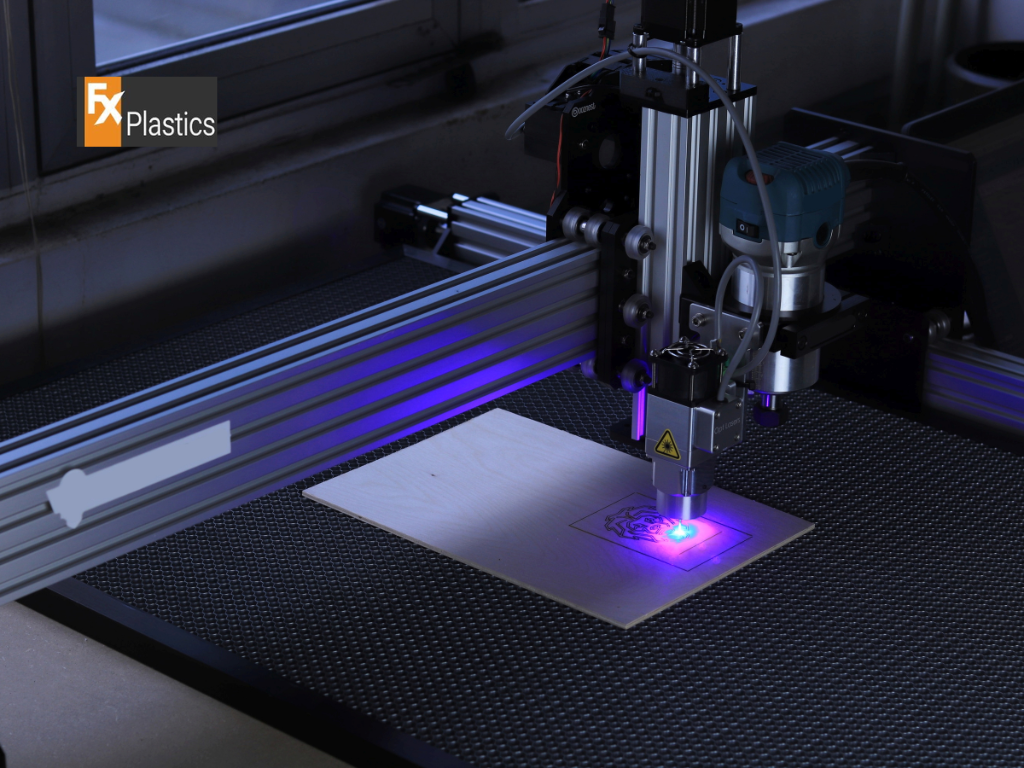

CNC laser cutting is known for being incredibly accurate. It uses a high-powered laser guided by a computer, which means it can follow even the most detailed designs with ease. Whether you’re cutting letters, patterns, or sharp curves, the result is always neat and clean.

Because the laser doesn’t actually touch the material, there’s less risk of wear or damage. You also get a smooth edge that doesn’t usually need sanding or extra work. This makes CNC laser cutting perfect for jobs that need fine detail and a polished finish.

Some materials don’t handle heat or pressure well. That’s where CNC laser cutting shines. It’s gentle enough for delicate jobs while still being strong enough to cut through solid materials.

It works great with Acrylic sheets, paper, cardboard, foam, and even fabric. The laser can make precise cuts without cracking or melting the edges. For soft metals and thin plastics, like those used in plastic cad projects, it gives fast, clean results with minimal waste.

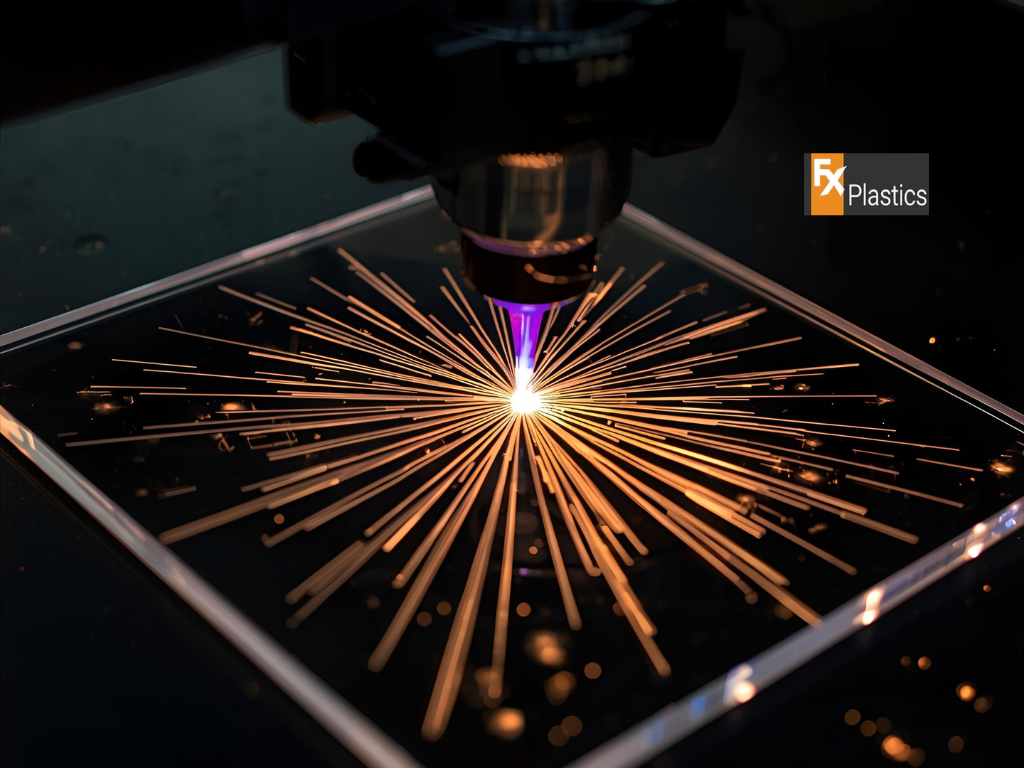

Plasma cutting uses hot plasma to slice through metal. It’s good for thick steel, but not ideal for more detailed work. The edges are rougher, and it often leaves behind slag or burn marks.

CNC laser cutting, on the other hand, gives much finer detail. The laser beam is much smaller and cleaner, which means your design turns out just the way you planned. Plus, there’s little to no cleanup needed afterward—saving you time and effort.

Plasma cutters generate a lot of heat, and that can cause thin materials to warp or bend. This is a problem when you’re working with lightweight metals, thin plastics, or plastic cad designs.

CNC laser cutting uses less heat and applies it more precisely. That means it doesn’t distort the material, even when cutting very fine lines or tight curves. For lightweight projects that need to stay flat and exact, it’s a much better choice.

Waterjet cutting uses high-pressure water mixed with abrasive particles. While it’s great for thick or heat-sensitive materials, it’s slower than CNC laser cutting and takes more time to set up.

Laser cutters start quickly, move fast, and can handle many types of materials in one session. There’s also no need to wait for water to drain or clean up messy slurry afterward. If you need a quick turnaround, laser is usually the better option.

Waterjet cutting isn’t always safe for certain plastics. For example, Acrylic sheets and acrylic screen panels can get cloudy or crack when cut with waterjets, especially if the pressure is too high.

With CNC laser cutting, you get sharp, polished edges that look professional and clean. It’s perfect for signs, displays, and custom panels made from Acrylic sheets—no clouding, no splintering, and no extra finishing needed.

Many people think CNC laser cutting is just for metal. But the truth is, it works with a wide variety of materials. From Acrylic sheets and wood to paper and textiles, laser cutting is extremely versatile.

That’s why it’s used in industries like signage, fashion, product design, and packaging. It’s also ideal for technical work like plastic cad prototypes, where detail and accuracy matter most. Whether you need simple shapes or complex cuts, the laser does it all with ease.

Designing an acrylic screen for an office, shop, or event display? You’ll want clean cuts and clear edges—without cracks or rough finishes. CNC laser cutting is perfect for this. It delivers a smooth, polished look right off the machine.

Unlike other methods, it won’t chip or warp the Acrylic sheets, even on curves or cut-outs. This makes it the top choice for designers who want precision and a high-end result.

If you’re working in the Sydney region, choosing Laser Cutting Western Sydney services means faster results and easier communication. You won’t need to wait for long-distance shipping or deal with delays. Local providers are also more flexible with urgent changes or updates.

Plus, when your design is ready to go, a nearby shop can review your file, test materials, and give instant feedback. Whether it’s your first time using CNC laser cutting or you’re an experienced designer, local help goes a long way.

Working with Laser Cutting Western Sydney professionals means more than just convenience—it means personal service. You can ask questions, get advice on materials like Acrylic sheets or plastic cad, and make adjustments without long wait times.

Local providers understand your industry and the specific needs of your project. They’re also more likely to offer help with design setup, file conversion, and material selection. That kind of support makes the whole process smoother from start to finish.

When choosing a cutting method, CNC laser cutting stands out for its versatility. It’s fast, accurate, and works on a wide range of materials. From acrylic screen displays to fine details on plastic cad models, it handles almost anything you throw at it.

It also creates less waste, needs less cleanup, and produces results that look professional without extra finishing. For most projects—especially those that need fine detail—it’s the smart, cost-effective choice.

In the end, the best cutting method depends on your project. If you’re cutting thick steel, maybe plasma or waterjet is best. But for sharp detail, smooth edges, and fast results—especially on materials like Acrylic sheets or thin plastics—CNC laser cutting wins.

Take time to consider your design, your material, and your timeline. And if you’re local, working with Laser Cutting Western Sydney services makes everything even easier.

More Blog

If you’re running a workshop, signage business, or custom build project in Western Sydney, precision

Supermarkets are busy places where customer interaction happens every few seconds. From checkout counters to

Modern businesses want materials that look good, last long, and offer creative flexibility. That’s why

When precision and design accuracy matter, cnc cutting services are a perfect solution. These services