When selecting materials for various applications, it’s essential to understand the differences and similarities between popular options like Perspex (a type of acrylic) and glass. Both materials are commonly used in construction, design, and manufacturing due to their transparency and aesthetic appeal. Comparing these materials helps in making informed decisions based on factors such as durability, safety, cost, and the specific requirements of a project.

Common Applications of Both Materials in Various Industries

Perspex and glass find applications in a wide range of industries. Glass is traditionally used in windows, drinkware, and art, while Perspex is popular in signage, display cases, and protective barriers. Both materials are also used in automotive, architectural, and interior design projects, each bringing its unique properties to the table.

Physical Properties of Perspex and Glass

Comparison of Strength and Durability

Perspex is generally more impact-resistant than glass, making it less likely to shatter upon impact. This durability makes it a preferred choice for high-traffic areas or applications where safety is a concern. Glass, while more brittle, often provides a higher level of scratch resistance and can maintain clarity over a longer period.

Differences in Weight and Flexibility

Perspex is lighter than glass, which can be an advantage in applications where weight is a concern, like in large installations or where structural load is an issue. It also offers more flexibility, allowing for more creative and versatile uses, especially in designs requiring bending or shaping.

Transparency and Aesthetic Qualities

Both Perspex and glass offer high levels of transparency, but they differ in aesthetic qualities. Glass typically has a more traditional and elegant appeal, with a high-luster finish. Perspex can have a similar appearance to glass but is more versatile in terms of tinting and coloring, allowing for a wider range of design possibilities.

Safety Considerations

| Aspect | Perspex (Acrylic) | Glass |

|---|---|---|

| Impact Resistance | High | Moderate to Low |

| Shatter Resistance | Shatters into larger, dull-edged pieces | Tends to break into sharp shards |

| Durability in High-Impact Situations | More durable, less likely to break | More likely to break or crack |

| Flexibility | More flexible, can absorb impacts better | Rigid, less tolerant to impacts |

| Weight | Lighter, easier to handle in larger sizes | Heavier, especially in thick layers |

| Safety in Breakage | Generally safer upon impact due to less sharp fragments | Potentially dangerous due to sharp shards |

| Preferred Use Cases | High-traffic areas, safety barriers, outdoor applications | Where aesthetic and clarity are prioritized, less exposed to impacts |

Safety Aspects in Handling and Installation

Perspex is easier and safer to handle and install compared to glass due to its lighter weight and resistance to shattering. This reduces the risk of injury during installation and maintenance, making it a preferable option in many construction and design projects.

Suitability for High-Risk Environments

In environments where safety and durability are critical – such as in sports arenas, schools, or high-traffic public areas – Perspex is often more suitable than glass. Its resistance to impact and shattering makes it a safer choice for areas prone to accidents or vandalism.

Cost Analysis

Price Comparison Between Perspex and Glass

When comparing prices, Perspex generally tends to be more expensive than traditional glass per unit. However, the cost can vary widely based on the thickness, quality, and any special treatments or coatings that each material may have. For specific projects, the total cost will also depend on the size and complexity of the design.

Factors Influencing the Cost of Each Material

Several factors influence the pricing of Perspex and glass:

- Material Quality: Higher grades of both materials typically come at a higher cost.

- Thickness and Size: Larger and thicker sheets are more expensive.

- Special Treatments: Costs can increase for tempered glass or UV-resistant Perspex.

Long-term Cost Implications of Both Options

While Perspex may have a higher upfront cost, its durability and lower likelihood of needing replacement can make it more cost-effective in the long run. Glass, while cheaper initially, may incur additional costs over time due to breakage or the need for specific cleaning products.

Installation and Fabrication

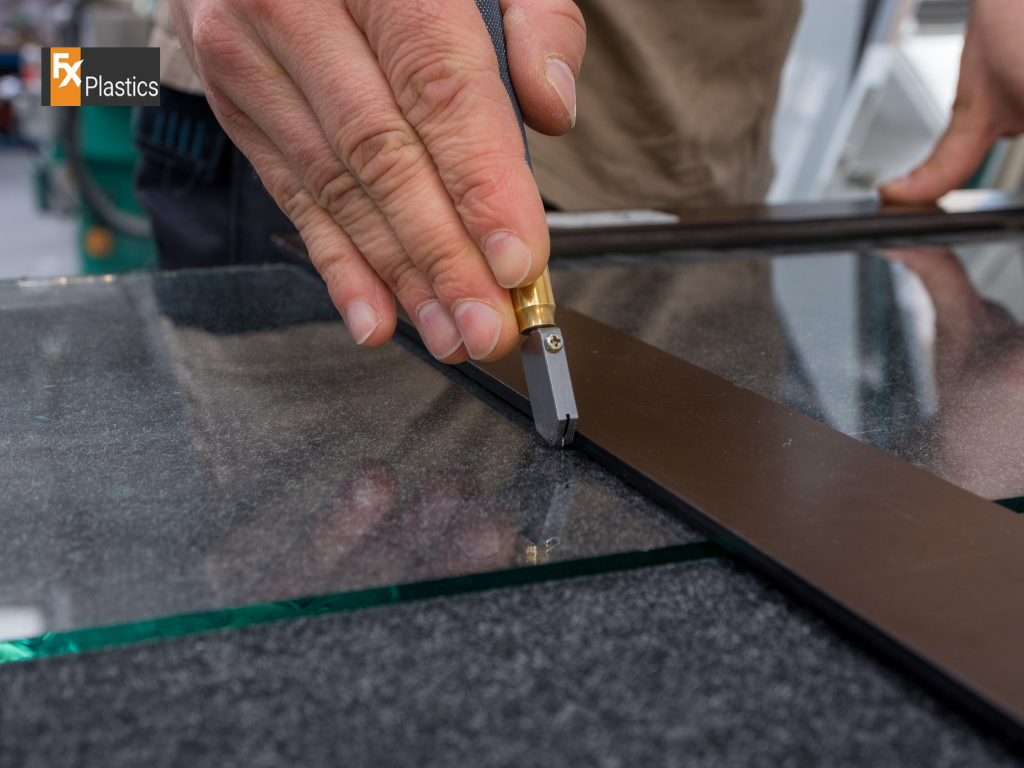

Ease of Cutting, Shaping, and Installing Perspex vs. Glass

Perspex is easier to cut and shape compared to glass, making it a favorable option for custom projects. It can be drilled, sawed, and routed without the risk of cracking or shattering, unlike glass.

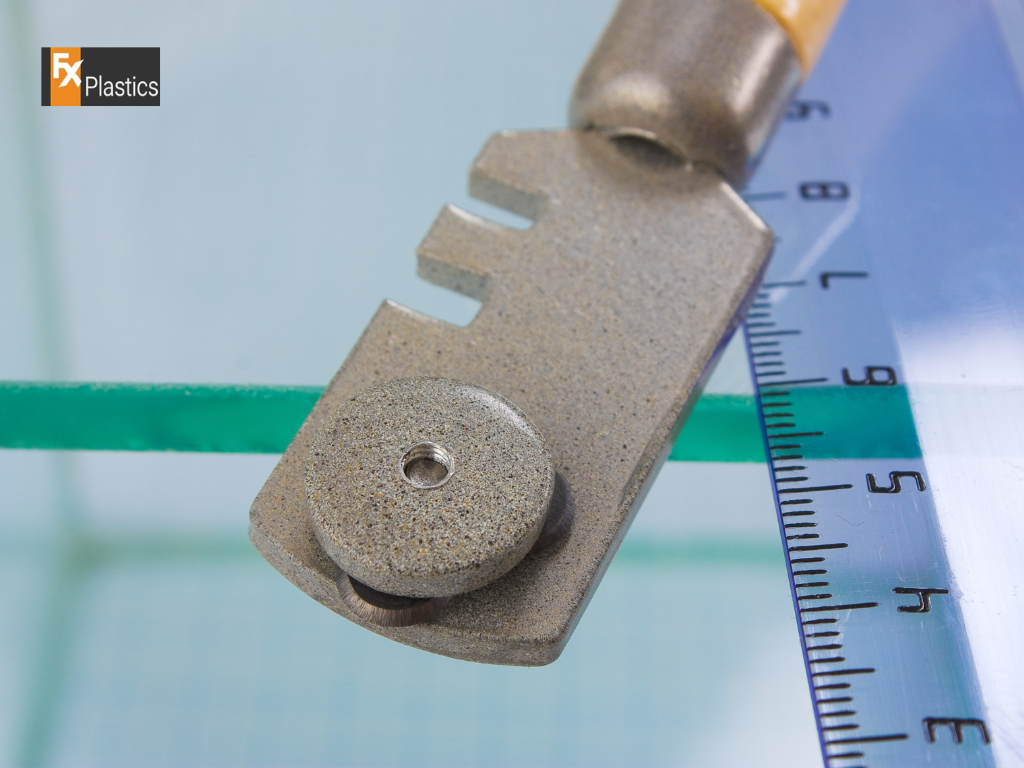

Requirements for Special Tools or Techniques

While basic tools can cut and shape Perspex, glass requires specialized glass-cutting tools. Glass installation also often demands more precision and care due to its fragility.

Considerations for DIY Projects vs. Professional Installation

DIY enthusiasts may find working with Perspex more manageable than glass. However, professional installation is recommended for large or complex projects, especially when dealing with glass, to ensure safety and accuracy.

Maintenance and Durability Over Time

Resistance to Weather and Environmental Factors

Perspex offers better resistance to weather and environmental factors, such as UV radiation and temperature fluctuations, compared to traditional glass. This makes it ideal for outdoor use where long-term exposure to elements is a factor.

Maintenance Requirements for Perspex and Glass

Both materials require regular cleaning for optimal appearance. Perspex, however, is more prone to scratching and may require special cleaning products. Glass, while scratch-resistant, can be more challenging to maintain if it breaks or cracks.

Longevity and Wear Over Time

In terms of longevity, Perspex often outlasts glass in demanding environments due to its higher impact resistance. Glass maintains its clarity over time but can be more susceptible to breakage, which impacts its overall lifespan.

Applications and Use Cases

Ideal Situations for Using Perspex

Perspex is particularly well-suited for situations where safety and durability are paramount. Its high impact resistance makes it ideal for use in high-traffic public areas, children’s play areas, or sports facilities. Perspex is also beneficial in outdoor settings due to its resistance to weathering and UV radiation. Its lightweight nature makes it suitable for large installations, such as display cases, signage, and skylights, where heavy glass might pose a risk or be impractical.

When Glass is the Preferable Option

Glass remains the preferred material in scenarios where aesthetic tradition and clarity over an extended period are crucial. For instance, in storefront windows, glass showcases, and certain architectural features, the classic elegance and crystal-clear transparency of glass are often desirable. Glass is also commonly used in situations where scratch resistance is important, such as in tabletops, picture frames, and some types of shelving.

Niche Applications Where One Material Outshines the Other

- Perspex: Perspex excels in applications requiring moulding and shaping, such as custom light fixtures, artistic installations, and innovative furniture designs.

- Glass: For precision optical applications, such as lenses and scientific equipment, glass is often preferred due to its optical clarity and consistency.

Conclusion

When choosing between Perspex and glass, consider the specific requirements of your project. For safety, flexibility, and lightweight needs, Perspex is likely the better choice. For traditional aesthetics, optical clarity, and scratch resistance, glass may be preferable. Always consider the long-term implications, including maintenance, durability, and cost, to ensure that the selected material aligns with your overall project goals and expectations.