Revolutionizing Manufacturing with CNC Routing and Machining

In the realm of modern manufacturing, CNC (Computer Numerical Control) routing and machining stand out as transformative technologies. These processes have not only streamlined the production of three-dimensional objects from 2D designs but have also introduced unprecedented levels of precision, efficiency, and versatility. By leveraging computerized systems to control the cutting, milling, and drilling of materials, CNC routing and machining open up a world of possibilities for creating complex shapes with high accuracy. This article delves into the intricacies of CNC routing and machining, exploring its advantages, applications, and the future it holds for manufacturing industries.

Understanding CNC Routing and Machining

A. The CNC Process Explained

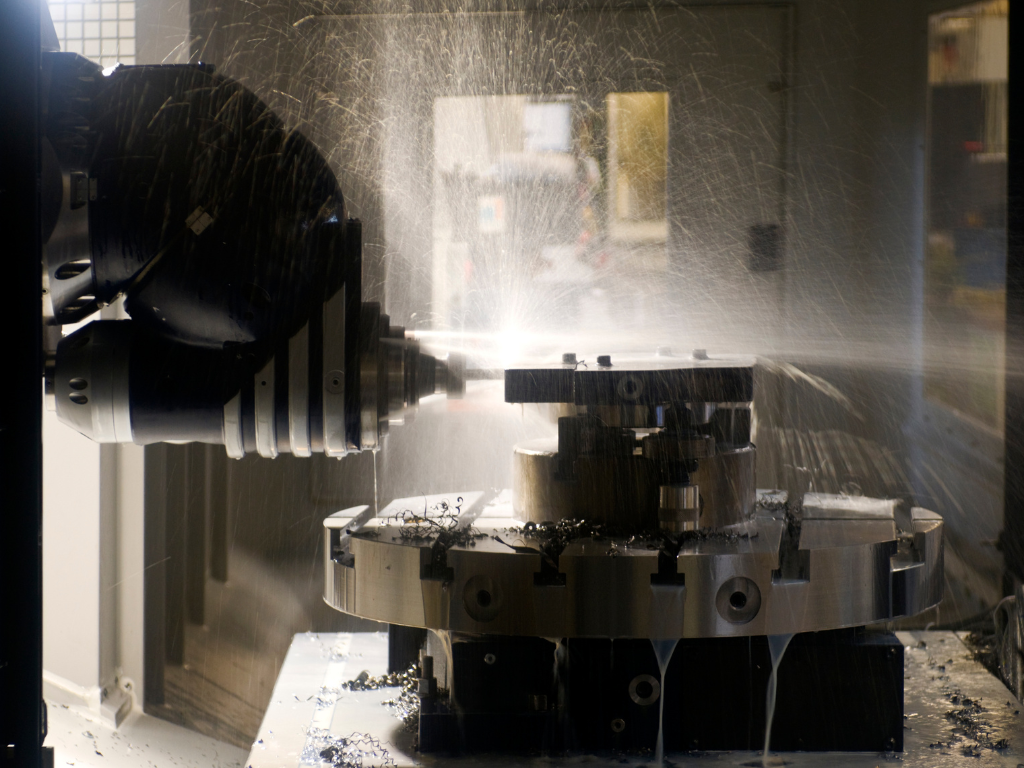

CNC routing and machining involve the use of computerized controls to guide cutting tools and shape materials into final products or components. This automated process translates designs from CAD (Computer-Aided Design) files into commands that the machine executes with precision. The versatility of CNC machines allows for a broad range of operations, including cutting, milling, and drilling, making it a cornerstone in modern manufacturing.

B. Evolution of CNC Technology

The evolution of CNC technology from manual controls to sophisticated computerized systems has dramatically enhanced manufacturing capabilities. Early numerical control machines laid the groundwork, but today’s CNC systems offer greater flexibility, speed, and precision, thanks to advancements in software and hardware.

C. Types of CNC Machines

The CNC umbrella encompasses a variety of machines, each suited to specific tasks:

- CNC Routers: Primarily used for cutting, carving, and engraving in materials like wood, metal, and plastics.

- CNC Mills: Versatile tools capable of performing complex cuts and shapes in a wide range of materials.

- CNC Lathes: Specialized in shaping materials through a rotational process, ideal for creating symmetrical objects.

Advantages of CNC Routing and Machining in Manufacturing

A. Precision and Accuracy

CNC machining’s hallmark is its ability to produce parts with exceptional precision and accuracy, crucial for industries where even the slightest deviation can have significant consequences.

B. Efficiency and Speed

Automation in CNC machining means that parts can be produced faster than traditional methods, with the added benefit of operating around the clock, significantly increasing production capabilities.

C. Versatility in Production

With the ability to handle a variety of materials and produce complex shapes, CNC machining caters to a broad spectrum of manufacturing needs, from custom one-offs to high-volume production.

D. Reduction in Material Waste

Precision cutting and efficient use of materials lead to minimal waste, making CNC machining not only cost-effective but also more environmentally friendly.

E. Cost-Effectiveness for High-Volume Production

While the initial investment in CNC machinery can be significant, the efficiency and speed of CNC machining make it highly cost-effective, particularly for large-scale production runs.

Applications of CNC Routing and Machining Across Industries

CNC routing and machining have found applications in virtually every sector of the manufacturing industry, thanks to their versatility and efficiency.

A. Aerospace and Automotive

In the aerospace and automotive sectors, where precision is paramount, CNC machining is used to produce complex components with tight tolerances. From engine parts to custom fittings, CNC technology ensures reliability and performance in high-stakes environments.

B. Medical Devices

The medical industry benefits from CNC machining in the production of surgical tools, implants, and diagnostic equipment. The ability to work with biocompatible materials and achieve the meticulous precision required for medical devices exemplifies the indispensability of CNC technology.

C. Custom Furniture and Woodworking

CNC routers have revolutionized the woodworking and furniture industries, enabling the creation of intricate designs, custom cabinetry, and architectural details with speed and precision that manual techniques cannot match.

D. Prototyping and Product Development

CNC machining plays a crucial role in prototyping and product development, allowing designers and engineers to rapidly iterate and refine their designs. The ability to quickly produce functional prototypes from CAD drawings accelerates the innovation process across all industries.

Challenges and Considerations in CNC Machining

Despite the numerous advantages and widespread applications of CNC routing and machining, there are several challenges and considerations that manufacturers must navigate.

A. Initial Investment Cost

The upfront cost of CNC machinery and software can be significant, making it a considerable investment for small and medium-sized enterprises. The decision to purchase should be weighed against the expected improvements in production efficiency and product quality.

B. Technical Skill Requirements

Operating CNC machines requires a specific set of skills, including knowledge of CAD software, machine operation, and programming. Training employees to proficiently use these machines adds another layer of cost and consideration for manufacturers.

C. Maintenance and Upkeep

To ensure the longevity and proper functioning of CNC machines, regular maintenance is crucial. This includes routine checks and calibration to prevent breakdowns and ensure consistent accuracy in production.

The Future of CNC Routing and Machining

As technology continues to evolve, the future of CNC routing and machining looks promising, with several advancements on the horizon that could further revolutionize manufacturing.

A. Technological Advancements

Future developments in CNC technology may include greater integration with AI and machine learning to optimize machining processes, predict maintenance needs, and enhance the precision and speed of production. Automation and robotics are also expected to play a larger role, allowing for even more efficient and autonomous manufacturing environments.

B. Expanding Applications

The versatility of CNC machining means its applications are continually expanding into new industries. As materials science advances, CNC machining will likely play a critical role in shaping innovative materials for use in sectors such as renewable energy, biotechnology, and nanotechnology.

C. Sustainability and Environmental Impact

There is a growing emphasis on sustainability within manufacturing, and CNC machining is no exception. Future advancements may focus on reducing power consumption, utilizing sustainable materials, and minimizing waste to ensure that CNC machining is not only efficient but also environmentally responsible.

The Impact of CNC Routing and Machining on Modern Manufacturing

CNC routing and machining have undeniably transformed the manufacturing landscape. By offering unparalleled precision, efficiency, and versatility, these technologies have enabled the production of complex parts and products that were once deemed impossible. The wide-ranging applications across industries—from aerospace to medical devices, and beyond—highlight the central role of CNC machining in modern manufacturing.

As we look toward the future, it is clear that CNC technology will continue to evolve, bringing with it new possibilities and challenges. The integration of advanced technologies such as AI, automation, and sustainable practices will further enhance the capabilities of CNC machining, ensuring its place at the heart of manufacturing innovation for years to come.

The journey of CNC routing and machining is a testament to the power of technology to drive progress, improve efficiencies, and create opportunities across the vast spectrum of industries. As manufacturers and engineers continue to push the boundaries of what’s possible, CNC machining will undoubtedly remain a cornerstone of their efforts, shaping the future of manufacturing in the process.

3 thoughts on “The Advantages of CNC Routing and Machining in Manufacturing”

Good post and straight to the point. I am not sure if this is actually

the best place to ask but do you guys have any thoughts on where to employ some professional

writers? Thank you 🙂 Najlepsze escape roomy

I like this web blog it’s a master piece! Glad I detected this on google.?

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?