Choosing the right material is one of the most important steps in any CNC project. The material affects everything from the precision of the cuts to the durability of the final product.

Whether you’re working with Acrylic sheets, wood, or metal, each material offers unique qualities that can enhance your design. Selecting the right one ensures your project meets both functional and aesthetic goals.

Materials like Acrylic sheets are perfect for projects requiring transparency and lightweight durability. Metals, on the other hand, provide unmatched strength and precision.

Using the correct material helps you achieve the desired finish and ensures the project stands the test of time. By combining the right material with professional cnc cutting services, you can create designs that are both intricate and durable.

Wood is one of the most popular materials for Design and Fabrication projects. It’s versatile, easy to work with, and provides a natural finish that appeals to many designers.

From furniture and decorative panels to intricate carvings, wood adapts to a wide range of applications. Its availability in various types and finishes makes it a go-to material for CNC routing and machining projects.

Different types of wood are suited for specific CNC applications:

Each type of wood offers unique benefits, making it easy to find one that fits your project.

Achieving clean, precise cuts with wood requires the right tools and techniques. Professional cnc cutting services ensure that your designs are executed flawlessly.

Key tips for clean cuts:

These steps ensure your wooden designs maintain their natural beauty while meeting your exact specifications.

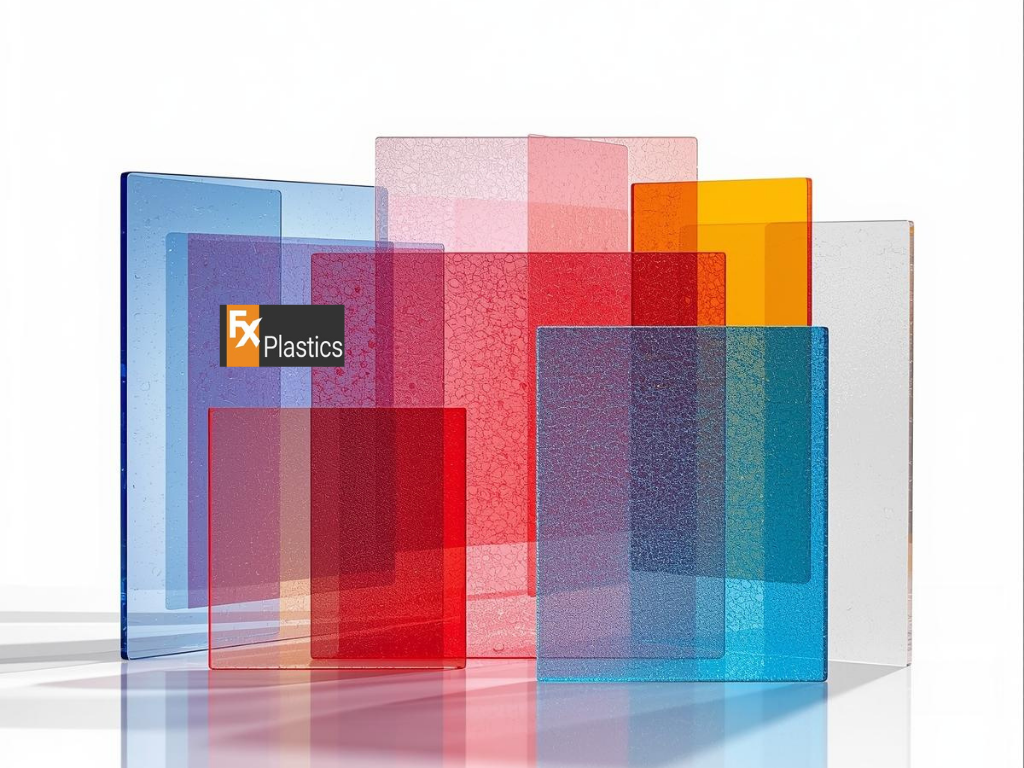

Acrylic sheets are highly durable, lightweight, and visually appealing. They offer a crystal-clear finish that mimics glass, making them perfect for projects requiring transparency.

Unlike glass, acrylic is shatter-resistant, making it safer and more versatile. It’s ideal for displays, signage, and even furniture, thanks to its flexibility and strength.

Using laser cut acrylic takes precision to the next level. CNC machines equipped with lasers can create smooth, detailed edges without the need for additional finishing.

Laser cutting is especially useful for intricate designs, as it ensures every line and curve is clean and sharp. This level of detail makes acrylic an excellent choice for Design and Fabrication projects that demand perfection.

Acrylic is widely used in:

Whether it’s a custom sign or an intricate display piece, Acrylic sheets paired with CNC laser cutting deliver stunning results.

Metals like aluminum and steel are staples in CNC machining. These materials are known for their strength, durability, and ability to maintain precision in intricate designs.

Aluminum is lightweight and versatile, making it great for components requiring strength without added weight. Steel, on the other hand, offers unmatched durability and is ideal for heavy-duty applications.

Metals are perfect for CNC laser cutting due to their ability to withstand high temperatures and retain sharp, clean edges. Laser cutting produces precise cuts and reduces the need for additional finishing, saving time and ensuring accuracy.

This makes metal an excellent choice for creating tools, industrial parts, and architectural elements.

Metals excel in various industries, such as:

The combination of precision and durability makes metal a top choice for advanced CNC machining projects.

Plastics such as PVC and polycarbonate are lightweight, affordable, and versatile. PVC is highly durable and commonly used for signage and piping, while polycarbonate offers impact resistance, making it ideal for protective barriers and panels.

These materials are easy to machine and adapt well to various design needs.

CNC cutting services play a crucial role in handling plastics. With precise cutting techniques, they ensure smooth edges and accurate dimensions, eliminating the need for additional polishing.

This is especially important for applications like displays and prototypes, where visual appeal and precision are key.

Plastics are widely used in:

Their versatility and affordability make plastics a go-to material for various CNC projects.

Composite materials combine two or more different materials to create a stronger, more versatile product. Examples include carbon fiber and fiberglass, which are lightweight yet incredibly durable.

Composites are often used in industries where strength and weight savings are critical, such as aerospace and sports equipment.

In Design and Fabrication, composites are used for:

Their adaptability makes them ideal for projects requiring both functionality and aesthetics.

Composites are best for projects that demand high strength-to-weight ratios or require resistance to extreme conditions. For example, they are preferred for aerospace components, where traditional materials may fall short.

If your design involves innovative shapes or textures, composites can offer more flexibility than standard options like metals or plastics.

From versatile Acrylic sheets to durable metals, each material brings unique advantages to CNC projects. Wood, plastics, and composites further expand your options, making it easier to match materials to your needs.

Professional services like CNC laser cutting and cnc cutting services make handling these materials seamless. They ensure precision, save time, and bring your designs to life with flawless results.

When choosing a material:

With the right material and skilled execution, your CNC project is sure to stand out!

More Blog

acrylic screens are made from a clear plastic material that offers excellent transparency and strength.

Acrylic fabrication is the process of turning acrylic plastic into finished products that people can

An acrylic screen is designed to handle everyday impact and pressure in a way that

An acrylic screen is a clear and lightweight alternative to glass that is designed for