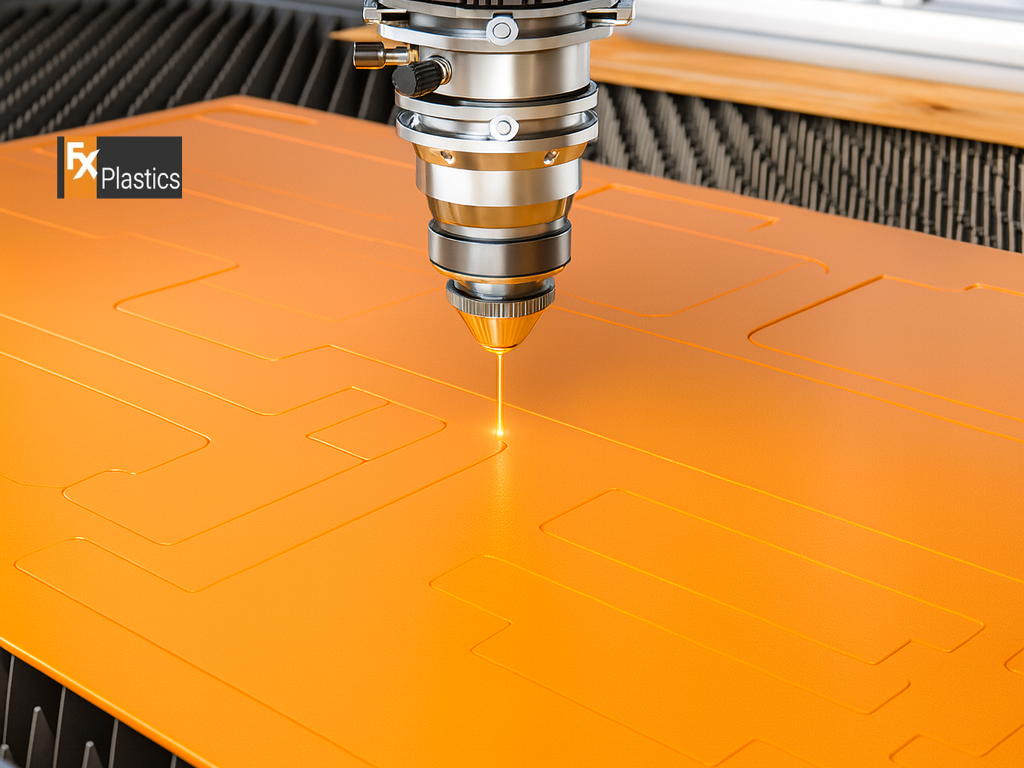

CNC laser cutting has propelled the signage industry into a new era, where the limitations of past production methods are replaced by the boundless possibilities of digital precision. The ability to cut intricate designs quickly and accurately has opened up new avenues for custom signage, enabling businesses to achieve distinct branding and visual communication like never before.

The shift towards CNC laser cutting in the creation of signage brings with it a host of advantages, fundamentally changing the approach to sign design and manufacturing.

One of the most significant benefits of CNC laser cutting is its precision. The technology allows for the creation of complex designs that would be difficult, if not impossible, to achieve through traditional methods. From delicate lettering to intricate logos, laser cutting executes every curve and angle with razor-sharp accuracy, ensuring that the final product precisely matches the original design.

CNC laser cutting’s adaptability extends to the variety of materials it can process. Whether it’s the sleek finish of cut metals, the smooth edges of acrylics, or the natural texture of wood, laser cutting handles each with ease. This versatility not only broadens the creative possibilities for signage but also allows for the selection of materials that best suit the sign’s intended environment and aesthetic.

Transforming an idea into a tangible sign requires a thoughtful design process, complemented by the right tools and software to bring that vision to life.

The journey from concept to creation begins with a clear understanding of the design’s requirements and constraints. Designers must consider the properties of the chosen material, the intricacies of the design, and how each element will come together in the final piece. This stage often involves sketching and prototyping to refine the concept before moving to digital design.

The preparation of designs for CNC laser cutting is facilitated by advanced CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software. These tools enable designers to create precise digital models of the signage, which are then used to guide the laser cutting process. Software like Adobe Illustrator, AutoCAD, and CorelDRAW are popular choices for designing laser-cut signs, offering powerful features that support the creation of detailed, cut-ready designs.

The choice of material plays a pivotal role in the success of CNC laser-cut signage, affecting everything from the aesthetics to the durability of the finished product.

When selecting materials for laser-cut signage, consider the following factors:

Different materials react uniquely under the laser, affecting the cutting process and the final appearance:

Achieving excellence in laser-cut signage involves more than just the cutting process; it extends to how the material is handled before and after.

The longevity of laser-cut signage greatly depends on proper installation and upkeep.

Producing laser-cut signage comes with its set of challenges, especially when dealing with intricate designs or aiming for material efficiency.

Intricate designs can elevate the aesthetics of signage but pose challenges in production. To navigate these:

Efficient material handling is crucial for cost-effective production and minimizing waste.

The evolution of laser-cut signage is ongoing, with new trends and innovations shaping its future.

Future trends likely to influence CNC laser-cut signage include:

Sustainability is becoming a key concern in signage production.

CNC laser-cut signage stands at the intersection of technology, art, and sustainability, offering businesses unparalleled opportunities to elevate their brand presence. By embracing innovative designs, optimizing production practices, and keeping an eye on future trends, companies can create signage that not only captures attention but also reflects their commitment to quality and environmental responsibility. As we move forward, the role of CNC laser cutting in signage production will continue to grow, driven by advancements in technology and a deeper understanding of its potential to transform spaces and brands.

More Blog

Modern businesses want materials that look good, last long, and offer creative flexibility. That’s why

When precision and design accuracy matter, cnc cutting services are a perfect solution. These services

In recent years, more people have started to ask questions about the environmental impact of

When people hear Design and Fabrication, they often think of big metal structures. But in