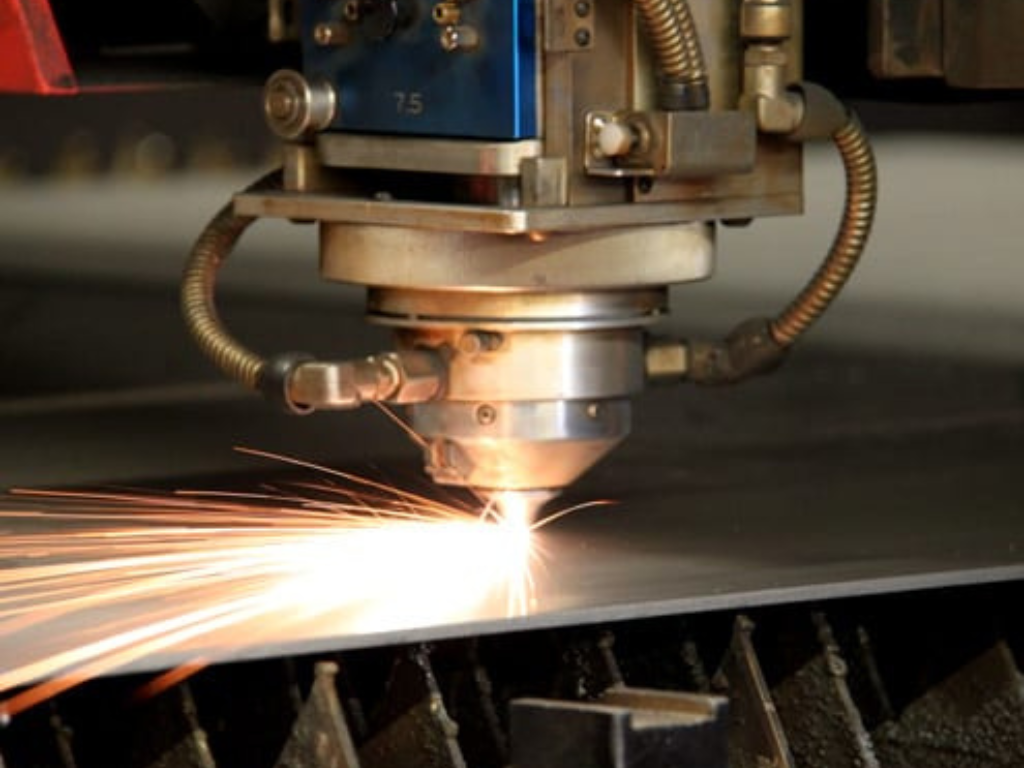

Acrylic SheetsBlogCNC laser cuttingCNC routing and machiningComputer aided drawing (CAD)DESIGN AND FABRICATIONDiamond Polisher

Advancements in Acrylic Sheets Technology: From Standard Sheets to High-Tech Uses

The Evolution of Acrylic Sheets Let’s start with a brief look back in time. Historically, acrylic sheets have been highly…